Hollow Rotary Actuators

DGII Series

- Integrated hollow table and closed-loop stepper motor

- Also available equipped with a servo motor

- Frame size 60~200 mm, diameter of hollow section φ20~100 mm

- High-strength, high precision positioning

- A thinner and easier-to-connect type than the conventional foot mount has been added to the motor horizontal mounting.

- A cross-roller bearing type has been added to the 60 mm motor vertical mounting frame size.

Features | Hollow Rotary Actuators DGII Series

Features of Actuator Section

Take the AZ Series as an example, and show the features of the DGII Series.

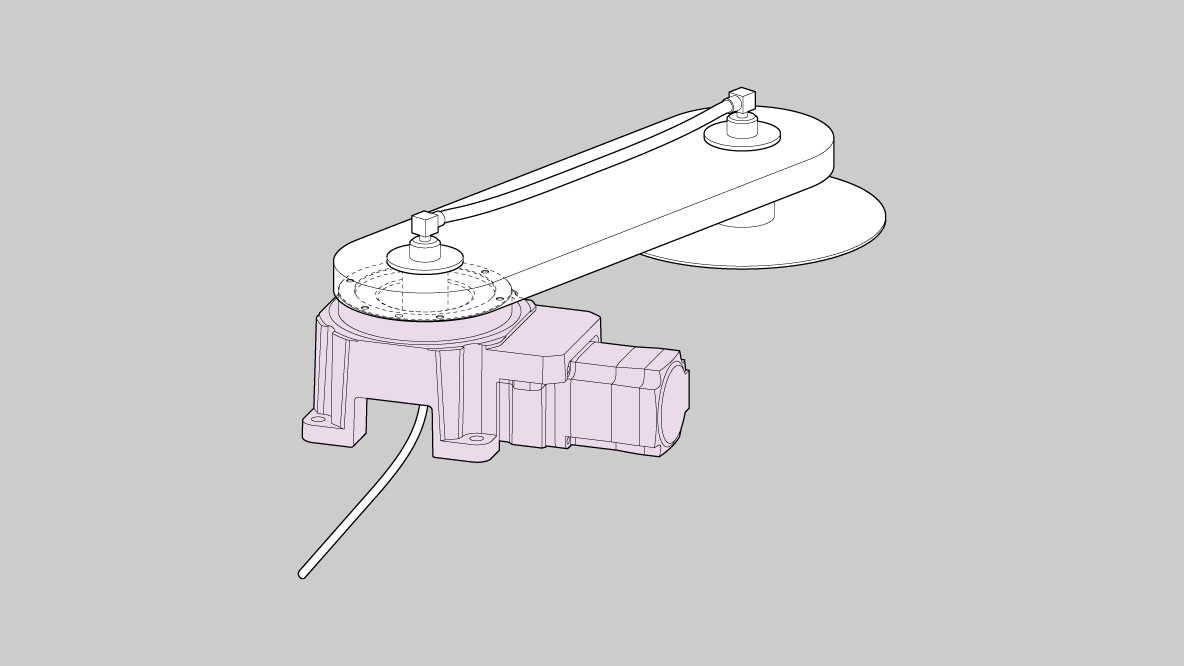

Direct Load Fastening is Possible

Loads with large inertia such as tables and arms can be installed directly on the output table, eliminating the need for connecting parts (collars), reducing design and assembly effort and parts costs.

Large-Diameter Hollow Output Table

Hollow holes can be used for wiring cables and for air and liquid piping.

High Strength

Can Drive Heavy and Large Loads

Maximum permissible axial load is 4000 N. Maximum permissible moment is 100 N・m. It can drive even a load with a large mass or inertia.

Small Surface Runout

Loads can be placed away from the center of the output table.

High Positioning Accuracy

| Motor Vertical Mounting | Motor Horizontal Mounting | Motor Horizontal Mounting (Foot mount) | |

|---|---|---|---|

| Backlash | Non-backlash | 3~10 arcmin | 6 arcmin |

| Repetitive Positioning Accuracy | ±15 arcsec (±0.004°) | ±15 arcsec (±0.004°) | ±30 arcsec (±0.008°) |

Integrated Structure to Reduce Equipment Setup Time

Reduce the Time Required for "Design," "Assembly," and "Adjustment"

Equipment tables and arms can be installed directly on the output table.

High Power Drive With Cross Roller Bearings

- The figure above shows the motor vertical mounting structure. As for the structure of the hollow output table, the same applies to the motor horizontal mounting.

Motor Direction That Can Be Selected to Fit the Space

- Motor vertical mounting, motor horizontal mounting, and motor horizontal (foot mount) are available. It can be selected according to the installation space in the equipment.

- The motor horizontal mounting is thin, allows the height from the mounting surface to be reduced. Additionally, because it is a connector type* motor, the connection is easy.

- *DC input frame size 60 mm is a cable type motor.

Click here for features and advantages of connector type motors

Advantages of Motor Horizontal Mounting (Foot mount)

- Machining of motor clearance holes is not necessary, thereby simplifying the mounting plate.

- Cables, pipes, etc. can be routed between the legs under the table.

Selectable Mounting Direction

The DGII Series can be installed horizontally, as well as on ceilings and walls, giving more options for equipment design.

Advantages Equipped With αSTEP AZ Series

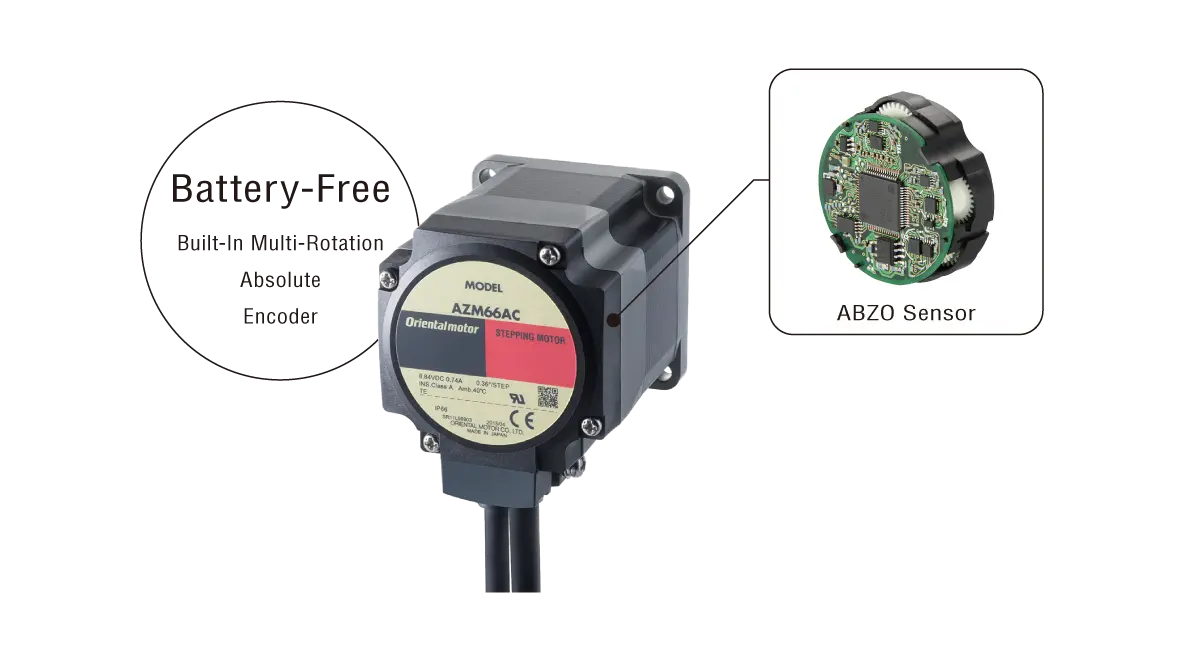

Battery-Free Absolute Encoder Equipped

It is equipped with a small battery-free mechanical absolute encoder (ABZO sensor). This can help improve productivity and reduce costs.

- Mechanical-Type Sensor

Retains positioning information even when power is not supplied - Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 (1,800) revolutions of the motor shaft from the home position

No External Sensors Required

As it is an absolute system, home sensors or limit sensors are not required.

Advantages

- Improved High-Speed Return-to-Home + Return-to-Home Accuracy

- Reduced Cost

- Simple Wiring

- Not Affected by External Sensor Malfunction

Battery-Free

Mechanical sensors do not require batteries.

Positioning information is managed mechanically by the ABZO Sensor.

Advantages

- No need to replace batteries

- Unlimited Driver Installation Possibilities

- Safe for Overseas Shipping

Simplifying the Main Program via Sequence Function

The AZ Series come equipped with a wide variety of sequence functions such as timer settings for linked operation and during operations, conditional branching, and loop operation. (excluding some models)

It can be set up using the support software MEXE02, which simplifies the sequence program of the host system.

- Positioning Operation Data Setting Value (max. 256)

- General-Purpose I/O Signal Counts (Input 10, Output 6)

- Communication I/O Signal Counts (Input 16, Output 16)

Convenient Operation and Setting

The AZ Series features allow you to drive:

Reduce Takt Time With Shortcut Operations

Move the shortest distance toward the set target position.

Example)

Moving from the 0° position to 270°, the shortest counterclockwise rotation direction is automatically selected and driven.

Set No-Entrance Area

Ensure equipment is not damaged by collisions with obstacles and work area is maintained.

Infinite Multi-Rotation is Possible

Equipped with a wrap function that can automatically reset the current position to "0°." Infinite multi-rotation operation is possible.

Reduces Equipment Setup Time

The parameters required to operate the hollow rotary actuator are set at the time of shipment. Contributes to reduced equipment setup time.

[Example of parameters set at the time of shipment]

- Home position

- Resolution (0.01°/step)

- Setting the rotation direction of the output table

- Wrap function setting (±180°)

- *Each initial setting value can be changed.

Applications and Usage Examples

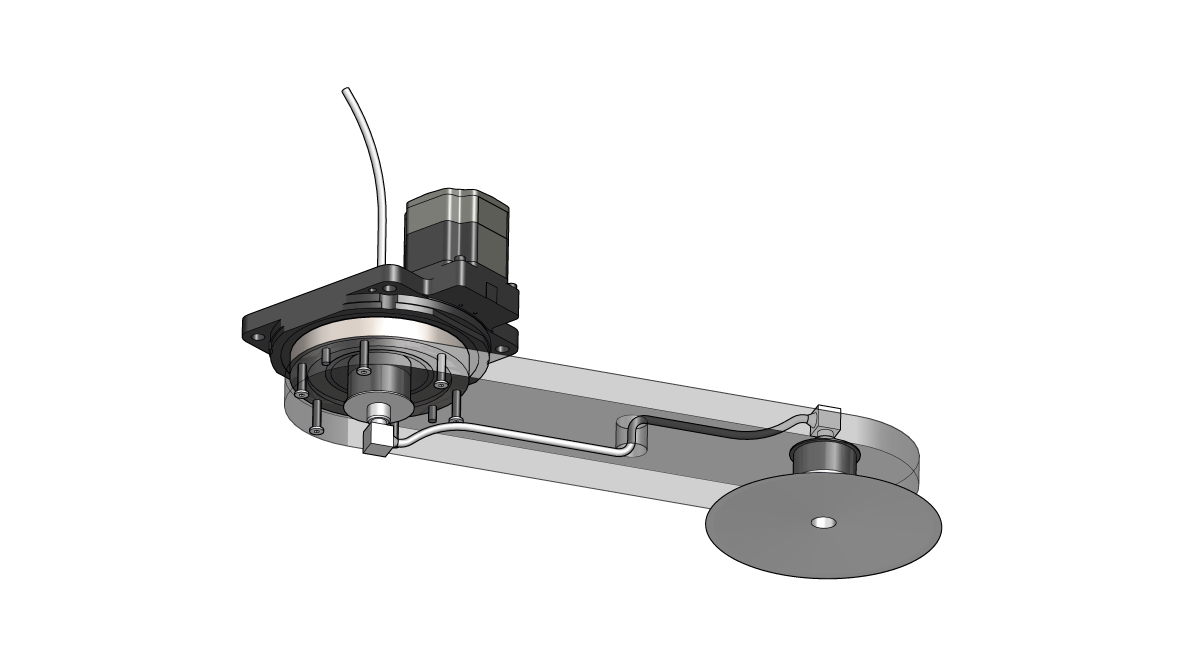

Applications Dealing With Load Moments

Low Speed and Low Vibration Applications

The microstep drive system and smooth drive function allow for low vibration rotary operation, even at low speeds.

Example) Liquid dispensing equipment

Even at low speed, stable and even dispensing is possible.

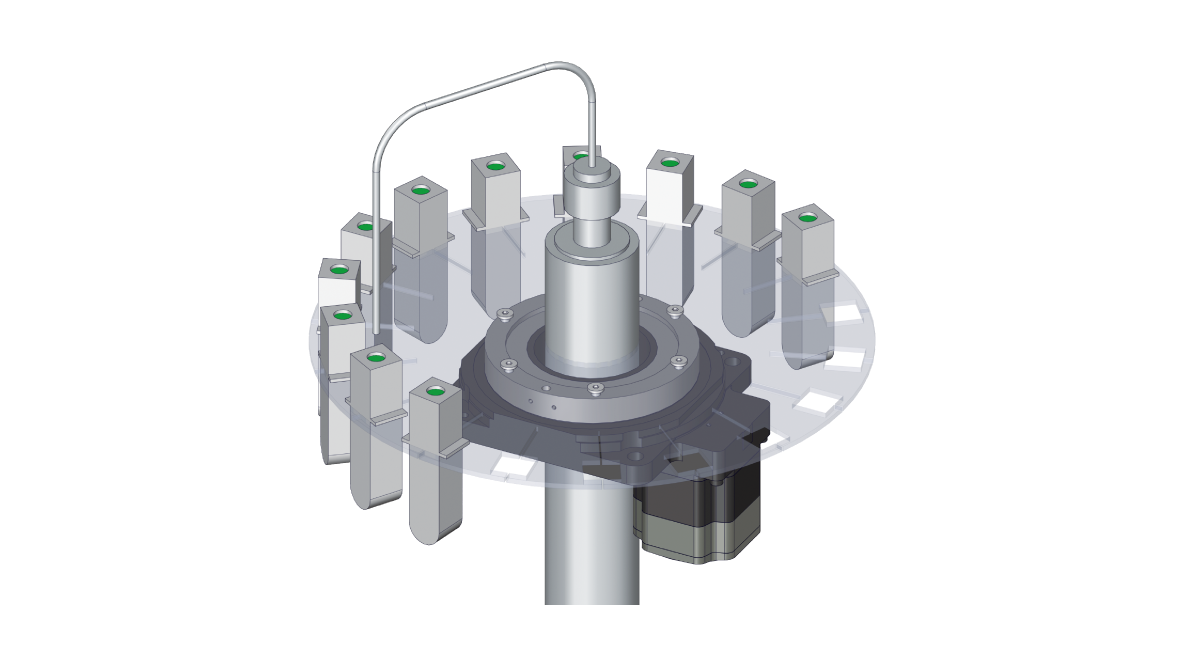

For High Precision Positioning Applications

It does not cause the phenomenon called "hunting," in which the shaft moves minutely when stopping. This is ideal for applications where vibration when stopping is a problem.

Example) Image inspection equipment

Accurate images can be captured because there is no hunting.

Applications With Varying Load Inertia

Since gain adjustment is not required, even for equipment with load fluctuations, can operate as set without the need for tuning.

Example) Disk manufacturing equipment

No tuning is required even if the number of discs to be transported changes.

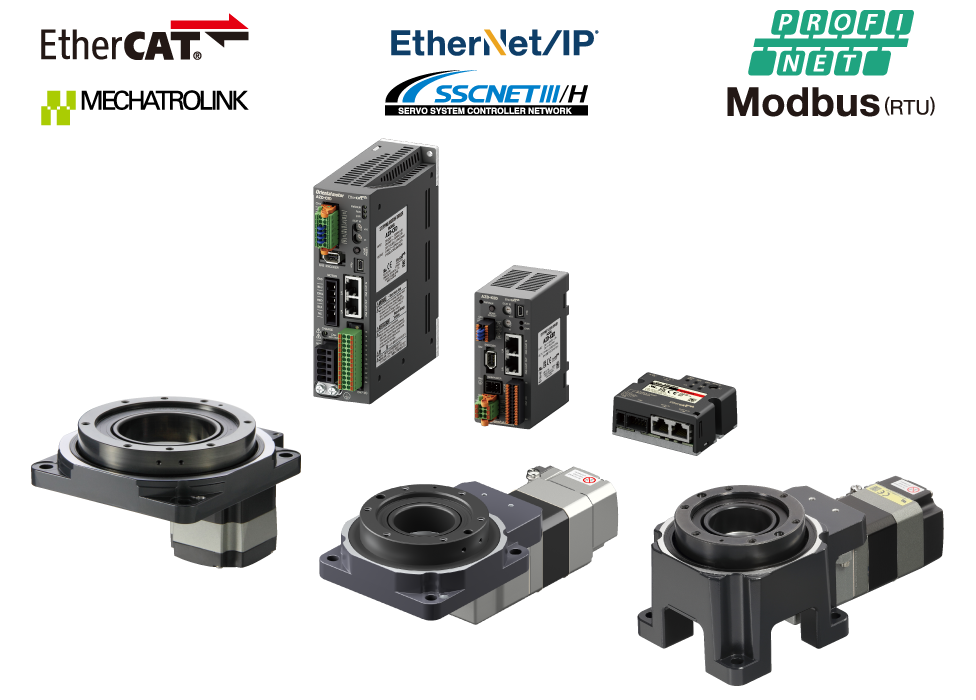

Drivers That Can Be Selected to Match the Host Controller

The lineup is available for a variety of controls, systems, and interfaces.

| Driver Type | Compatible Interfaces | Single Axis Driver | |||

|---|---|---|---|---|---|

| AC Input | DC Input | ||||

AZ Series Equipped |

AZX Series Equipped |

AZ Series Equipped |

|||

| Network Compatible | Direct control of the driver from a upper-level control device via industrial network |

EtherCAT | ○ | ○ | ○ |

| EtherNet/IP™ | ○ | ○ | ○ | ||

| PROFINET | ○ | ○ | ○ | ||

| MECHATROLINK-III | ○ | - | - | ||

| SSCNET III/H | ○ | - | - | ||

| Built-In Controller | Operation data is built into the driver. Controllable via Modbus (RTU) and I/O. Can be controlled via CC-Link by using a network converter. |

Modbus (RTU) I/O CC-Link* |

○ | - | ○ |

| Pulse Input With RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU) |

Pulse input Modbus (RTU) |

○ | - | ○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ | - | ○ |

- DC input mini Driver and multi-axis driver lineups are also available.

- *Available when using a network converter (sold separately).

AZ Series Equipped Product Line

Since the motors equipped are the same, the operating and maintenance methods are the same.

Electric Actuators (AZ Series equipped)

| Electric Linear Slide | Electric Cylinder | Compact Electric Cylinder | Rack-and-Pinion System | Electric Gripper | Hollow Rotary Actuator |

|---|---|---|---|---|---|

| EAS Series EZS Series EZSH Series |

EAC Series | DR Series DRS2 Series |

L Series | EH Series | DGII Series |

- The power supply input of the equipped motor differs between series. Refer to each series page for the detailed product line.

Features Equipped With Servo Motor AZX Series

Servo Motor With a Battery-Free Built-In Absolute Encoder

The servo motor AZX Series used as the drive motor is equipped with the same battery-free mechanical absolute encoder (ABZO Sensor) as the AZ Series.

This servo motor is specialized for positioning and continuous operation.

- Mechanical-Type Sensor

Keeps position information even when not powered - Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 revolutions (1800 revolutions) of the motor shaft from the reference home position

- Refer to here for details on AZX Series.

The Basic Operation Method is the Same As Those Equipped With the AZ Series

The basic operation method for models equipped with the AZX Series is the same as those equipped with the AZ Series.

The AZX Series and the AZ Series can be used together in the same equipment without the hassle associated with changes in operability.

| Wiring | Signal system wiring |

|---|---|

| Setting | Functions and setting methods of switches and parameters (Using MEXE02) |

| Control | Command ID number when controlling over a network |

| Operation Functions | Positioning operation functions built into the driver, etc. |

Achieves High Torque in the High Speed Range

The model equipped with the AZX Series achieves high torque in the high speed range.

It is suitable for positioning applications with a large amount of travel and continuous operation applications.

- This is a comparison of the speed - torque characteristics of models equipped with the AZX Series and models equipped with the AZ Series.

Models equipped with the AZX Series offer superior torque in the high speed range, models equipped with the AZ Series are better in the low speed range.

Cable Outlet Direction Can Be Changed

Since the model equipped with the AZX Series is installed using a coupling, the cable outlet direction can be changed by removing the motor and changing its orientation.

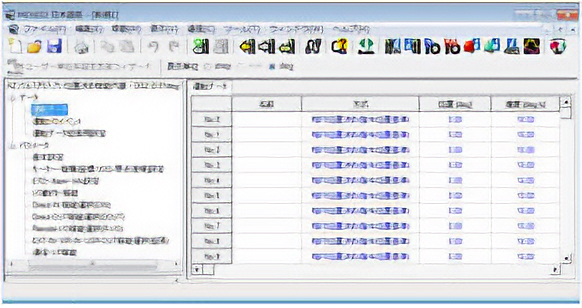

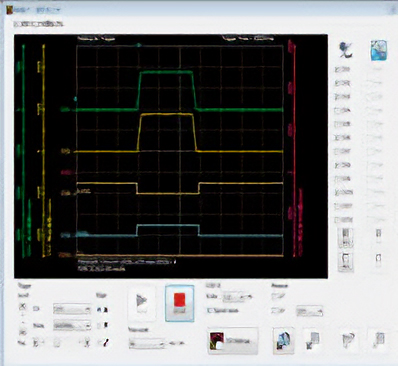

Support Software, Monitoring Functions

Easy Drive From PC with Support Software MEXE02

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as teach and monitor various conditions.

Click Here to Download the Support Software

Comprehensive Support From Start-up to Maintenance with a Variety of Functions

-

Startup and Evaluation

Useful functions for wiring check and test operation are provided.

- Setting and Saving of Operation Data

- I/O Monitoring

- Teaching, Remote Operation

-

Adjustment

The following functions are available to help you adjust motor operation after the equipment is installed.

- Waveform Monitoring

-

Diagnosis and Maintenance

Diagnostic and maintenance functions are available for trouble diagnosis and maintenance after operation is started.

- Alarm Monitoring

- Unit Information Monitor

- Status Monitor

-

Operation Data/Parameter Setting Screen -

Waveform Monitoring

Can Be Operated in Conjunction With Collaborative Robots as an Accessory

This can be used for turning of axes around the robot.

Products for Combination (Common to FANUC UNIVERSAL ROBOTS)

-

- Hollow Rotary Actuators

- DGII Series equipped with AZ Series (DC input)

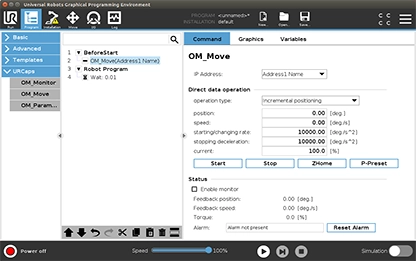

Universal Robots Certified Application

Can Be Controlled Directly From URCap

URCap *1 dedicated to the DGII Series allows control of the universal robot and the DGII Series in conjunction. You can set and change the travel amount and speed, etc. from the universal robot teaching pendant.

UNIVERSAL ROBOTS Product Specifications

-

- URCap

- OM_DG2-x.x.x.urcap *2

-

- Supported Series

- e-Series

-

- PolyScope Version

- PolyScope 5.12.2 or higher

URCap and setup manual are available.

URCap

Setup Manual

- *1 URCap is a graphical programming interface for universal robots.

- *2 x.x.x. contains version information.

Compatible Peripheral Devices for FANUC Plugin

Directly Controllable From Tablet TP

This plugin software dedicated to the DGII Series allows control of the CRX Series and the DGII Series in conjunction. No external control devices such as PLCs are required, and the FANUC Tablet TP can be used to set and change the travel amount and speed.

FANUC Product Specifications

-

- Plugin Software

- ORIENTALMOTOR_AZ.ipl

-

- Supported Series

- CRX Series

The software option "User Socket Message Function (A05B-2600-R648)" is required.

Plugin software and setup manual are available.

Plugin Software

Setup Manual

Note

Inquiries about UNIVERSAL ROBOTS or FANUC products are not covered by our support.

Related Products

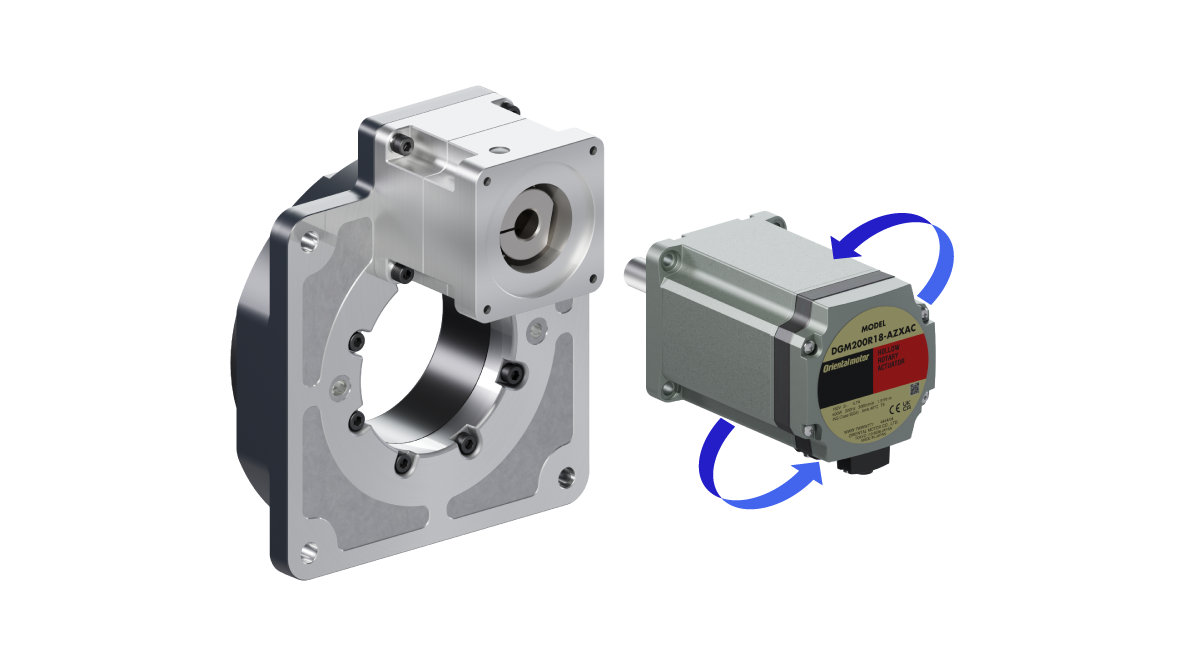

DGII Series Hollow Rotary Gearhead

The single DGII Series actuator unit (hollow rotary gearhead). The actuator structure of the DGII Series remains the same and is used in combination with servo motors of various companies through coupling connection. Suitable for large-inertia drive applications.

Click here for an alternative product

DGN130R2-18

DGN200R2-18

AZ Series mini Driver DC Input

This is a mini driver designed to be more compact and lightweight than a box-style driver. Also compatible with battery power supply, so it can be used for an even wider range of applications than before.

AZ Series Multi-Axis Driver DC Input

You can connect the Oriental Motor AZ Series DC input motors and electric actuators equipped with such motors.

-

2-Axis Type -

3-Axis Type -

4-Axis Type -

NEW

Slim Type

(4 axes)

- The slim type is only compatible with EtherCAT. For more details, please contact your nearest branch, sales office, or Customer Support Center.

- *EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- *MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

- *SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

Narrow down Products

Download

Catalog

Operating Manual

Support Software

URCap/Setup Manual

Plugin Software/Setup Manual

Lineup and Related Information

Combination With Other Manufacturers' Products