Brushless Motors

Motor Only

- Can be Combined with Customer-Designed Driver (Drive circuit)

- Motor Specifications such as Winding Resistance, Inductance, Induced Voltage Constants, Maximum Permissible Current Required for the Combination with the Driver are Available

- A High Strength and Low Noise Gearhead is Available

- 24/48 VDC

- Output Power 15 to 400 W

If you would like more details, please request through the website's Inquiry Form.

Features | Brushless Motor, Motor Only

Product Line

Compact, lightweight, and highly efficient brushless motor. The 24 VDC Type product line has rated output power of 15 W~100 W.

Round Shaft Type

| Output Shaft Type | Rated Voltage [V] |

Frame Size [mm] |

Output Power [W] |

Mass [kg] |

IP classification | Product Name |

|---|---|---|---|---|---|---|

|

24 VDC | 42 | 15 | 0.25 | IP40 | BLHM015K-A |

| 30 | 0.27 | IP40 | BLM030DHK-A | |||

| 24 VDC | 60 | 30 | 0.5 | IP40 | BLHM230K-A | |

| IP65 | BLHM230KC-A | |||||

| 50 | 0.47 | IP40 | BLM250DHK-A | |||

| 24 VDC | 80 | 50 | 0.8 | IP40 | BLHM450K-A | |

| IP65 | BLHM450KC-A | |||||

| 24 VDC | 90 | 100 | 1.4 | IP40 | BLHM5100K-A | |

| IP65 | BLHM5100KC-A | |||||

| 24 VDC | 104 | 200 | 2.4 | IP40 | BLVM620K-A | |

| 48 VDC | 400 | BLVM640N-A |

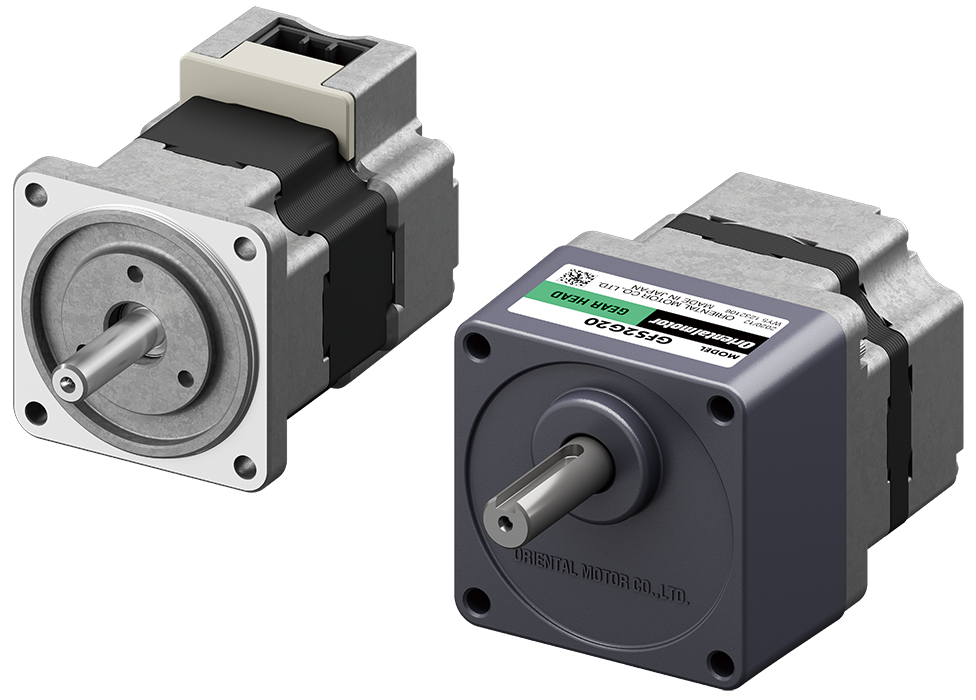

Combination With Gearhead

High-Strength, Low-Noise Gearhead for Increased Torque

Various types of high-strength, low-noise dedicated gearheads are available for brushless motors.

Utilization of the gearhead produces a large torque that cannot be generated by the motor alone, enabling a large-inertia drive.

In addition, the speed fluctuation in response to changes in load can be minimized due to the deceleration effect of the gearheads.

| Gearhead Type | Parallel Shaft Gearhead GFS Gearhead |

CS Geared Motor | Hollow Shaft Flat Gearhead FR Gearhead |

|---|---|---|---|

| External View |

|

|

|

| Features |

|

|

|

| Motor Output Power [W] |

15, 30, 50, 100, 200, 400 | 30, 50 | 30, 50, 100, 200, 400 |

| Gear Ratio | 5, 10, 15, 20, 30, 50, 100, 200*2 |

5, 10, 15, 20 | 5, 10, 15, 20, 30, 50, 100, 200*3 |

- *1

- The 15 W products have a rated life of 5000 hours.

- *2

- The gear ratio of 15 W products is 5~100.

- *3

- The gear ratio of 200 W products is 10~100. The gear ratio of 400 W products is 5~100.

Motor/Gearhead Product Line

A number indicating the gear ratio is specified where the box □ is located in the product name.

| Output Shaft Type | Rated Voltage [V] |

Frame Size [mm] |

Output Power [W] |

Mass [kg] |

IP classification | Product Name (Motor/Gearhead) |

|---|---|---|---|---|---|---|

|

GFS Gearhead

|

24 VDC | 42 | 15 | 0.5 | IP40 | BLHM015K-□*1 |

| 24 VDC | 60 | 30 | 0.88*2 | IP40 | BLHM230K-GFS /GFS2G□ |

|

| IP65 | BLHM230KC-GFS /GFS2G□ |

|||||

| 24 VDC | 80 | 50 | 1.69*2 | IP40 | BLHM450K-GFS /GFS4G□ |

|

| IP65 | BLHM450KC-GFS /GFS4G□ |

|||||

| 24 VDC | 90 | 100 | 2.8*2 | IP40 | BLHM5100K-GFS /GFS5G□ |

|

| IP65 | BLHM5100K-GFS /GFS5G□ |

|||||

| 24 VDC | 110 | 200 | 5.4*2 | IP40 | BLVM620K-GFS /GFS6G□ |

|

| 48 VDC | 400 | BLVM640N-GFS /GFS6G□ |

||||

|

24 VDC | 42 | 30 | 0.44 | IP40 | BLM030DHK-□CS |

| 24 VDC | 60 | 50 | 0.87 | IP40 | BLM250DHK-□CS | |

|

FR Gearhead

|

24 VDC | 60 | 30 | 1.3 | IP40 | BLHM230K-GFS /GFS2G□FR |

| IP65 | BLHM230KC-GFS /GFS2G□FR |

|||||

| 24 VDC | 80 | 50 | 2.4 | IP40 | BLHM450K-GFS /GFS4G□FR |

|

| IP65 | BLHM450KC-GFS /GFS4G□FR |

|||||

| 24 VDC | 90 | 100 | 3.6 | IP40 | BLHM5100K-GFS /GFS5G□FR |

|

| IP65 | BLHM5100K-GFS /GFS5G□FR |

|||||

| 24 VDC | 104 | 200 | 7.2 | IP40 | BLVM620K-GFS /GFS6G□FR |

|

| 48 VDC | 400 | BLVM640N-GFS /GFS6G□FR |

- *1

- The 15 W product is a geared motor in which the motor and gearhead are integrated.

- *2

- When the gear ratio is 200.

Brushless Motor Features

Structure

Oriental Motor brushless motors are of the inner rotor type.

The rotor is inside the stator, and permanent magnets are placed on its surface. Since the rotor is thin and has a small inertia, it has high responsiveness during acceleration and deceleration.

Also, the stator is located close to the surface of the motor, making it a compact motor with good heat dissipation and high output power.

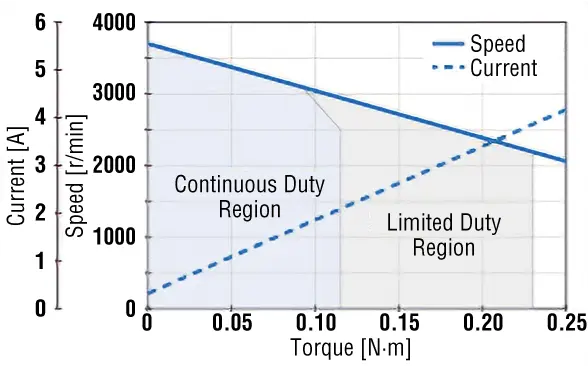

Power Performance

-

Torque Curve Has Small Speed Fluctuation

Since the torque design focuses on the practical range from mid to low speeds, it is characterized by low fluctuations in speed relative to load changes.

BLHM230K-A(□60 mm-30 W)Driver Power Wupply Voltage: 24 VDC

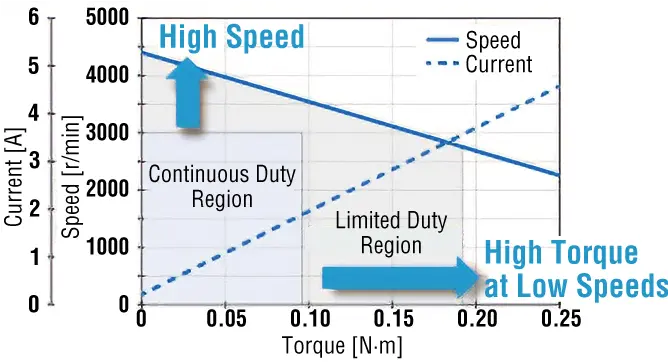

-

High-Speed and Low-Speed High-Torque Ranges Can Also be Utilized

In combination with customer-designed drivers, the high-speed range and low-speed, high-torque operating range can also be utilized.

(Limited Duty Region)

Contributes to increased performance of applications.BLM030DHK-A(□42 mm-30 W)Driver Power Wupply Voltage: 24 VDC

-

High Torque Generated per Unit of Current

The large torque constant design allows a small motor to drive a high load.

It can also be used with leeway in areas where torque is capped by current limits due to power supply or circuit constraints.

Reliability and Low Vibration

-

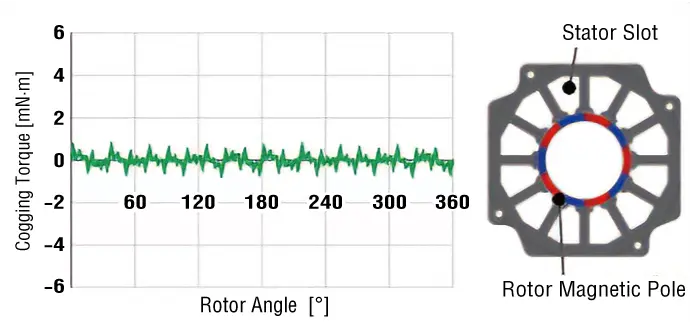

Low Cogging Torque

Low cogging torque is achieved by using the correct combination of rotor poles and stator slots.

Smooth rotation with reduced vibration and uneven rotation at low speeds.

-

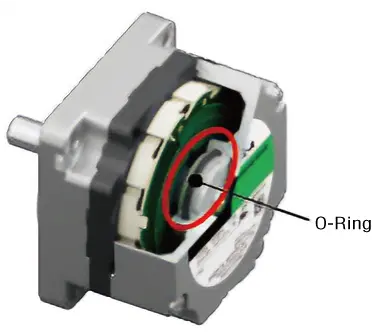

High Resistance to Eccentric Load

Creep resistance is improved by attaching an O-ring to the bearing's outer ring. (Only round shaft* connector type). It can be used safely for fan and pump applications.

- *Round shaft is a type that the load could directly attached to the motor rotating shaft.

-

Vibration Suppression Using Rotor Balancing

Rotor imbalance is suppressed by inspection and adjustment. Smooth rotation with reduced vibration and uneven rotation in the mid to high-speed range.

Stand-Alone Brushless Motor Specifications

Please refer to the PDF below for the typical specifications and characteristics of the motor only.

Typical specification of a stand-alone brushless motor (round shaft type)

- The motor specifications (hall sensors, excitation sequences, connector pin assignments) required for combination with drivers, please contact your nearest Oriental Motor sales office.

Applications

-

AGV

- Compact, high output power

- Stable during both high and low speeds

- Low heat generation even with 24-hour operation

-

Medical Testing and Analytical Equipment

- Low vibration with smooth startup and shutdown contributes to the improved specifications of the equipment

- Low noise and improved equipment quietness

- Global compatibility in one model

-

Pump

- Longer equipment life due to the use of high-temperature resistant bearings

- Anti-creep structure withstands applications prone to eccentric loads

- Low heat generation prevents specimen alteration

-

Security Gates/Automatic Doors

- Compact design that fits inside the enclosure

- Fast and smooth opening and closing

- Stable speed even with load fluctuations due to wind

-

Agitator

- Stable speed even with load fluctuations

- Low heat generation and continuous operation

- Fewer failures than conventional models due to the anti-creep structure

Dedicated drivers are also available (Only for motors of 100 W or less)

Compact board type drivers that can drive the motors listed above are also available.

Sine wave drive ensures smooth rotation and low noise and vibration.

Analog setting type, digital setting type, and RS-485 communication type are available.