Stepper Motor PKP Series/

CVD Series Pulse Input Driver

- DC input

- Compact drivers

- High torque, low vibration, low noise

- Pulse Input

Features | Stepper Motors PKP Series/CVD Series Pulse Input Driver

Improved Performance

Low vibration, high torque, and high efficiency features are introduced here.

Low Vibration

Full-time microstep drive with full digital control has greatly improved the vibration level, resulting in lower vibration in all speed ranges.

Significantly Improved Vibration Characteristics in All Speed Ranges

5-Phase Motor for Even Lower Vibration

Higher Torque

High torque is achieved by combining a high-current driver and a motor with an optimized winding design.

- PKP Series Motor: Higher torque due to revised winding design

- CVD Series Driver: High current drive is possible due to higher efficiency of the drive circuit

2-Phase Motor Increased Torque in Low Speed Range

5-Phase Motor Increased Torque in All Speed Ranges

High Efficiency Design

The CVD Series achieves higher torque by increasing the output current compared to conventional products. The design takes into consideration the reduction of heat generation so that the output current can be increased.

Driver Features

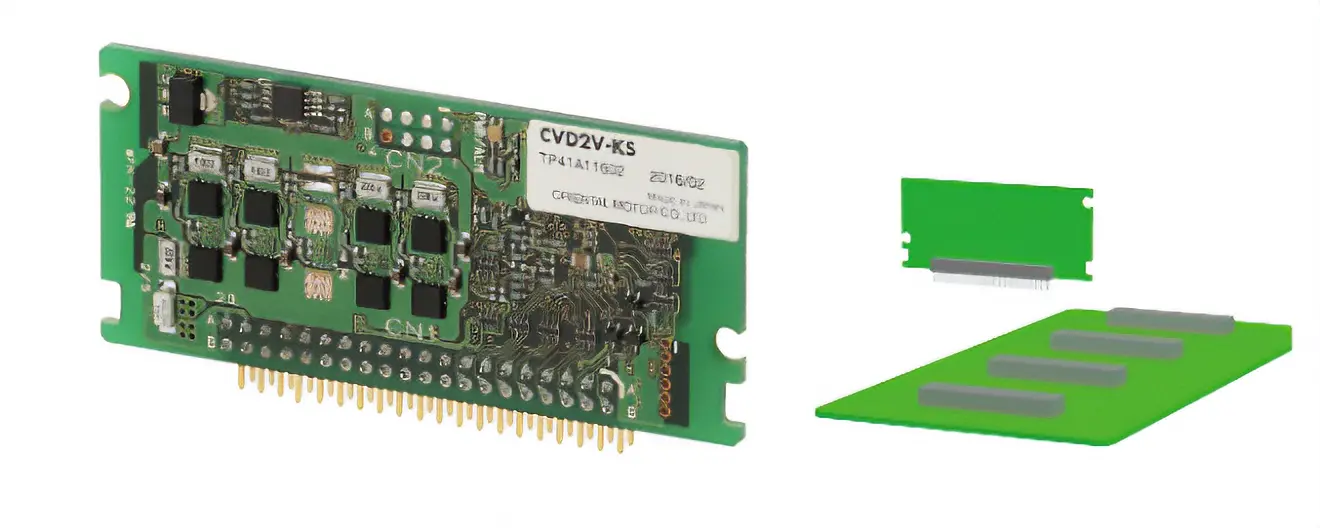

Industry's-Top-Class Compact High Performance Driver

Compact and lightweight drivers that contribute to space saving. The size, installation, I/O and power connectors for 2-phase and 5-phase drivers are the same.

| Size | Mass |

|---|---|

| W 85 mm × D 52.5 mm × H 24.5 mm | 20~70 g |

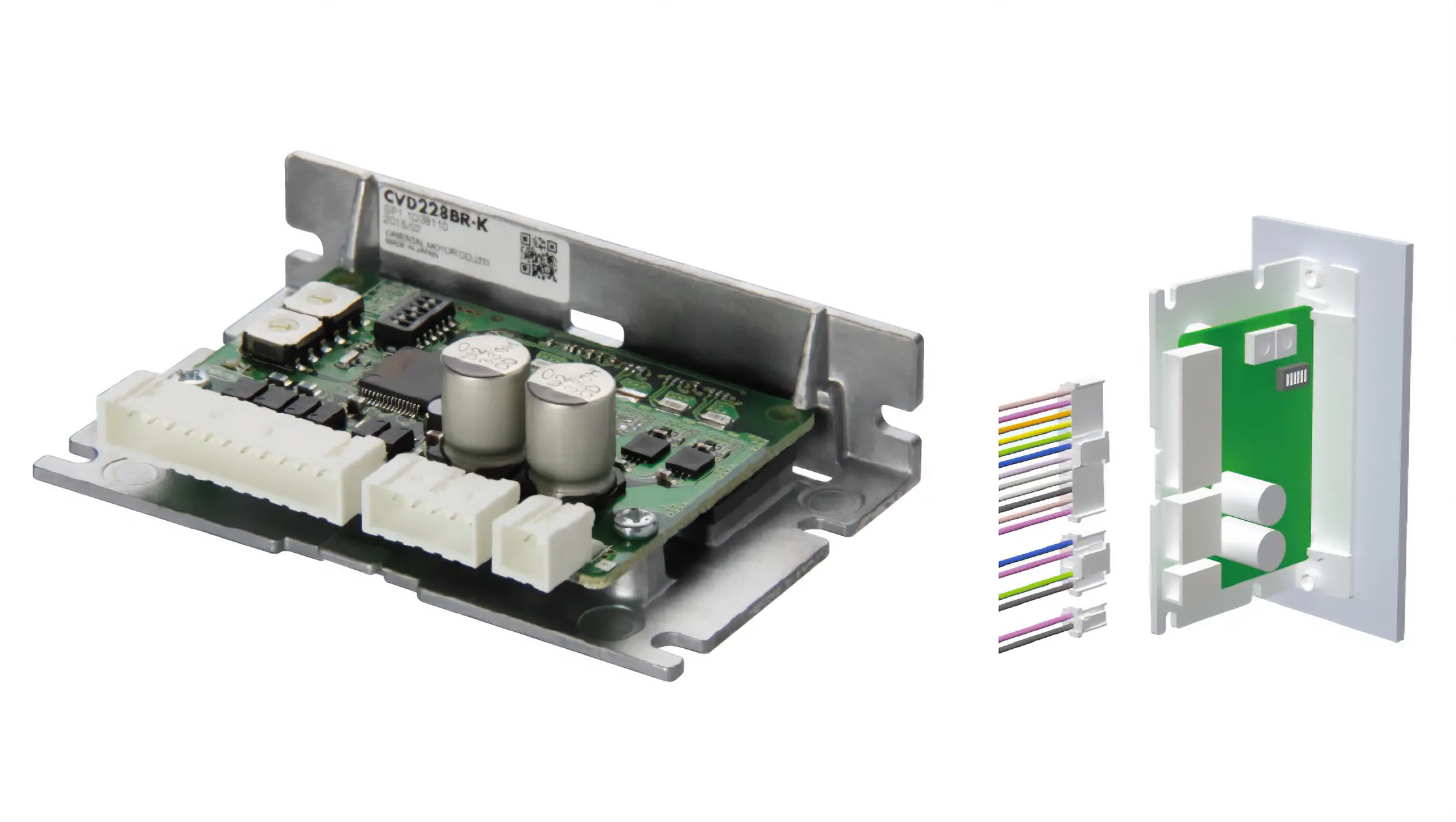

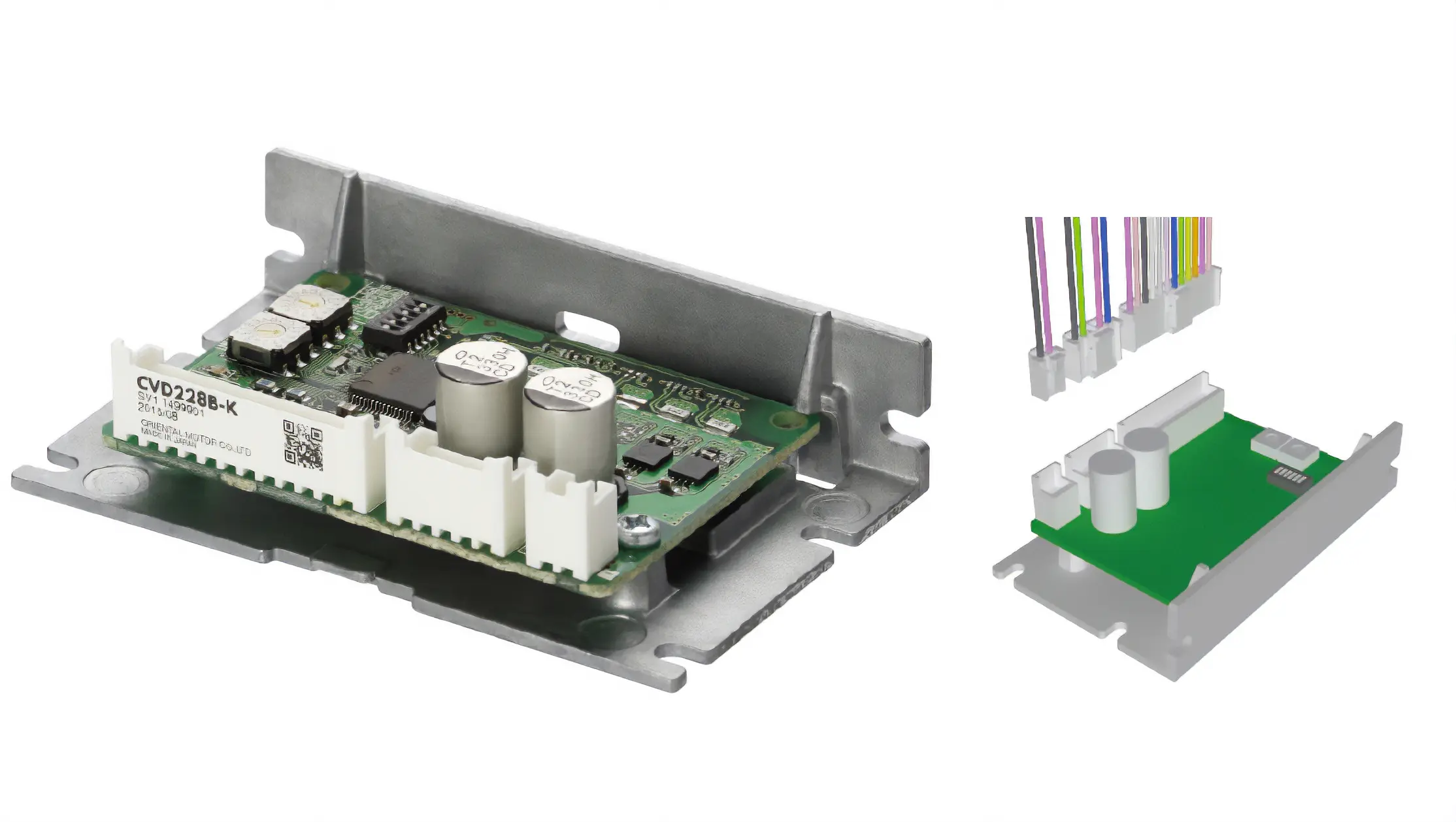

Driver That Can be Selected According to the Installation Method

Drivers with different shapes and connector orientations are available to match the installation method.

Right-Angle Type With Mounting Plate

The connector faces outwards.

With Mounting Plate

The connector faces upwards.

Examples of driver installation

Motor Types

2-Phase Stepper Motors

| Classification | Type | Frame Size [mm] |

Basic Step Angle [°] |

Additional Function |

|---|---|---|---|---|

| No Gearhead |

|

13~85 | 1.8 | Encoder, electromagnetic brake |

|

28~56.4 | 0.9 | Encoder, electromagnetic brake |

|

|

42, 60 | 1.8 | None | |

| With Gearhead |

|

28~90 | 0.05~0.5 | Encoder |

|

28~60 | 0.09~0.36 | None | |

|

51, 61 | 0.018~0.036 | None |

Click here for information about PKP Series 2-phase stepper motors

5-Phase Stepper Motors

| Classification | Type | Frame Size [mm] |

Basic Step Angle [°] |

Additional Function |

|---|---|---|---|---|

| No Gearhead |

Standard

|

20~85 | 0.72 | Encoder |

|

28, 42, 60 | 0.36 | Encoder | |

| With Gearhead |

|

42, 60 | 0.024~0.2 | None |

Click here for information about 5-Phase Stepper Motor PKP Series

Selection of the Motor That Best Suits Your Application

The torque of 2-phase stepper motors in the low speed range and 5-phase stepper motors primarily in the high speed range has been greatly increased. You can select a motor suited to your specifications from a wide range of speeds and torques.

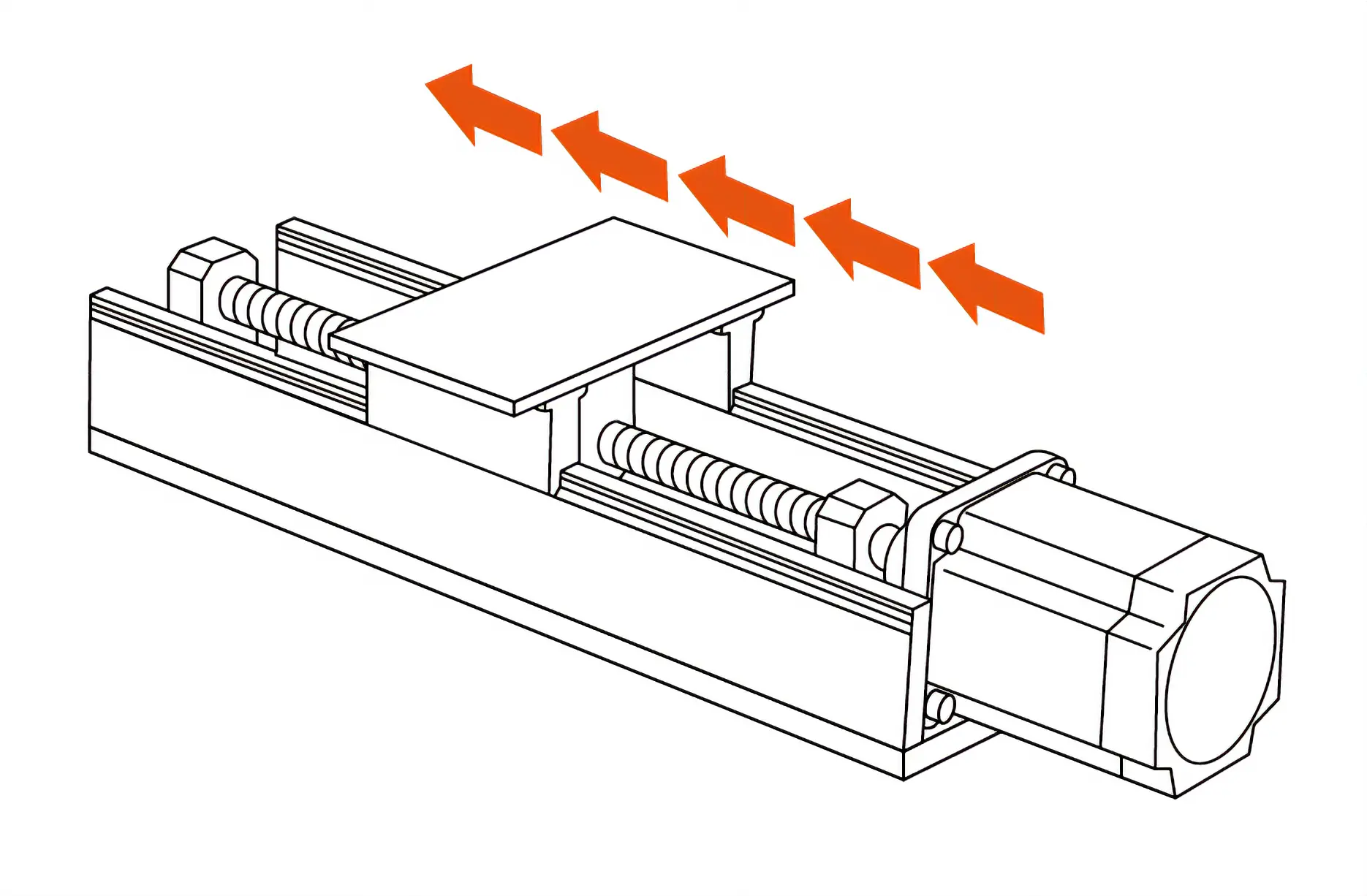

Application: Inching operation over short distances.

For applications that require rapid acceleration and deceleration, a 2-phase stepper motor with high-torque at low speed is recommended.

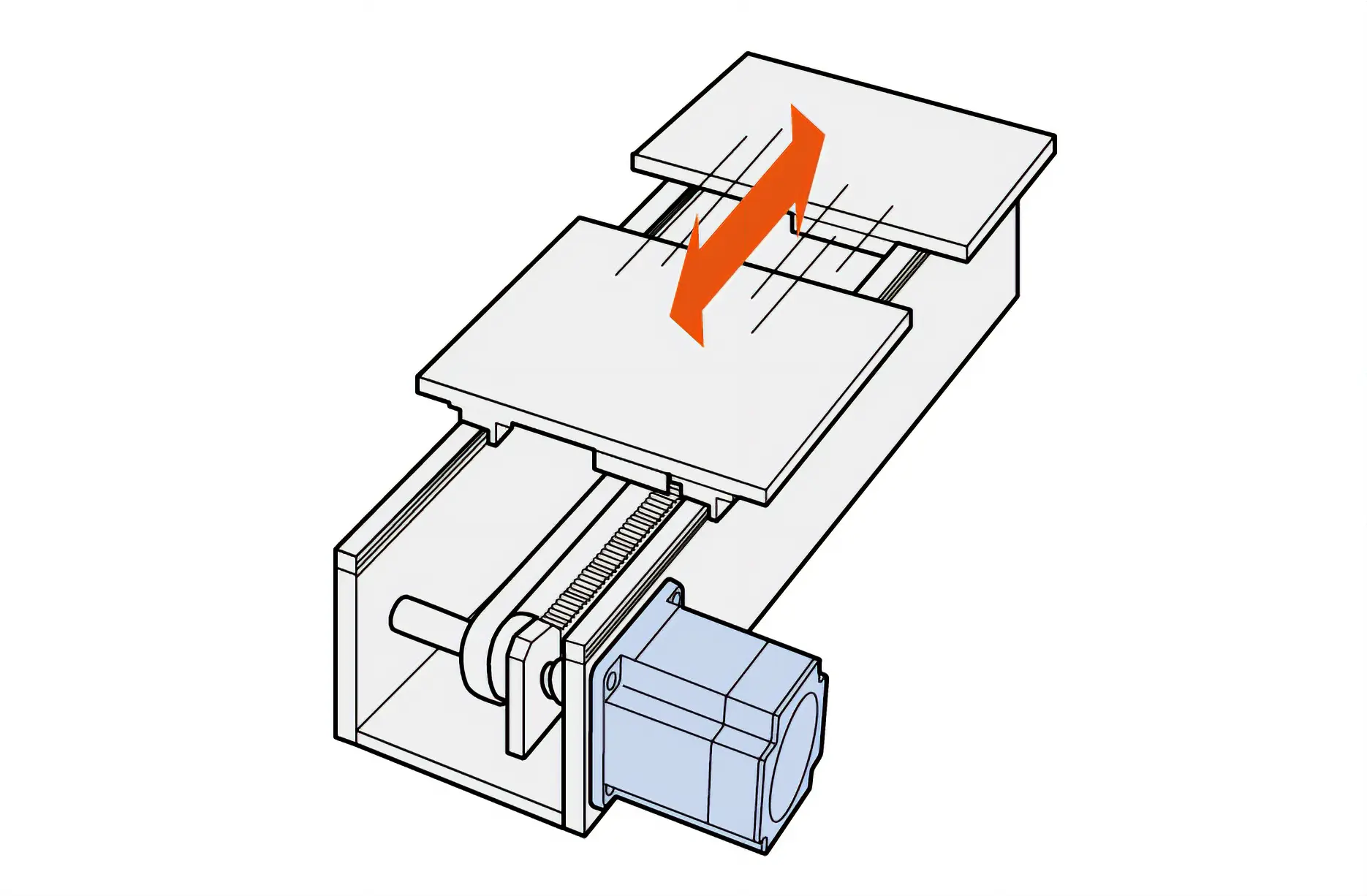

Application: Long distance back-and-forth operation.

For applications that require high-speed range, a 5-phase stepper motor with high-speed torque is recommended.

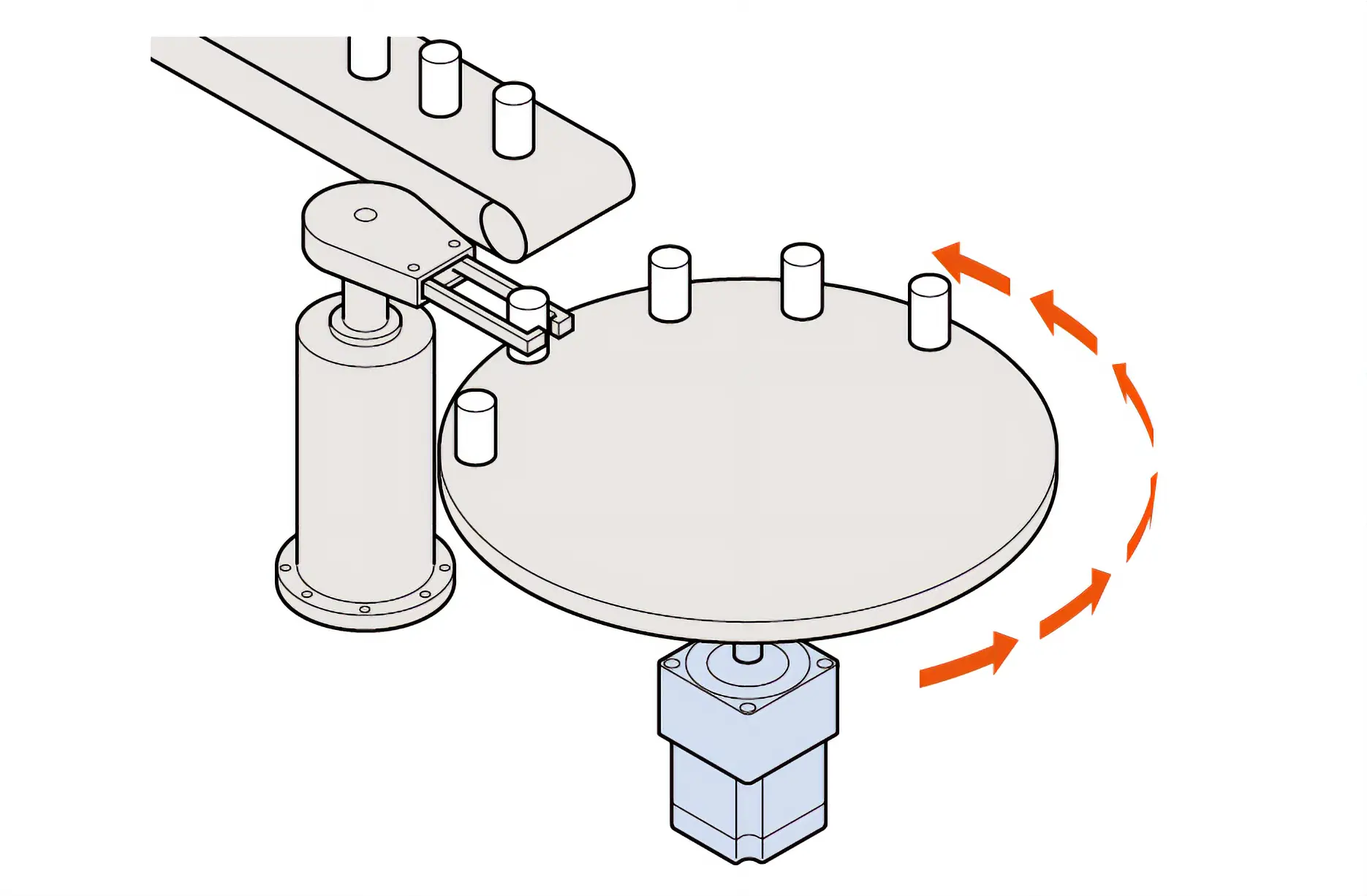

Application: Inching operation over short distances with large amount of inertia.

For applications that require acceleration and deceleration with higher torque, geared types are recommended.

Related Products

Stepper Motor PKP Series/

CVD Series RS-485 Communication Type Driver

You want to run a stepper motor under Modbus (RTU) control. You want set data easily on a touch screen. This product combines a motor with a driver that supports RS-485 communication compatible to meet such needs. Up to 31 axes of drivers can be controlled by connecting them to a single host control device.

Bipolar Driver for 2-Phase Stepper Motors

Driver for 5-Phase Stepper Motors

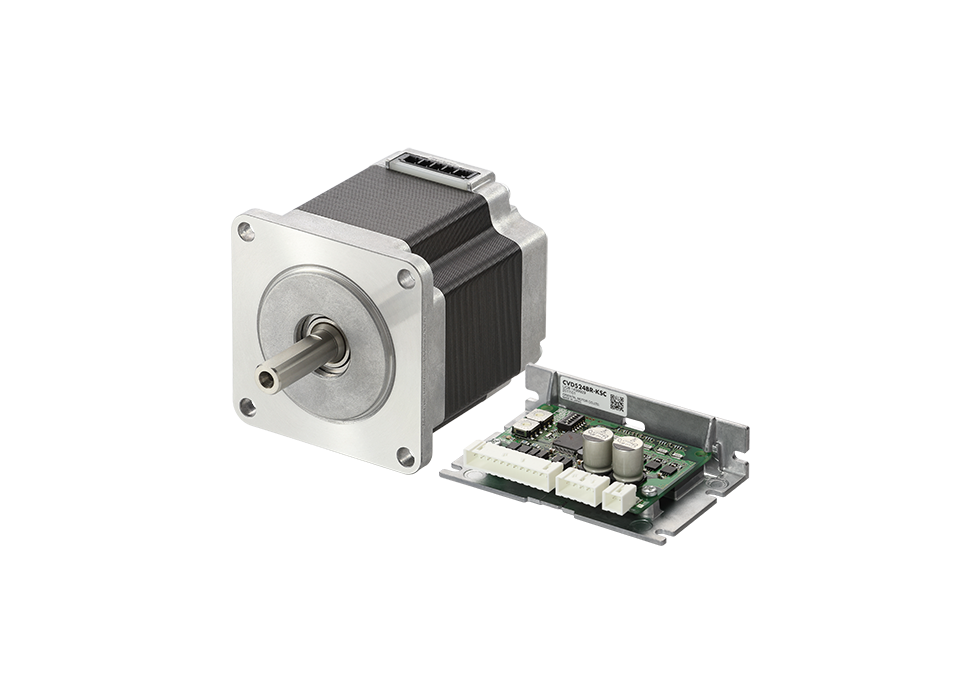

CVD Series S Type

These are DC input drivers for 2-phase and 5-phase stepper motors.

Board type compact drivers are available, one to control motor positioning via SPI communication and the other to control by pulse input.

Stepper Motor PKP Series/

CVD Series SC Type Driver

Easy speed control by clockwise rotation and reverse inputs without using a pulse generator. You can use it like a speed control motor. Simple system configuration with only a 5-phase motor, driver, and programmable controller.

Hollow Rotary Actuator DH Series

This actuator is a 5-phase stepper motor with a hollow flange on the output shaft. Loads can be attached directly to the flange surface. Air piping, wiring, and rays can be passed through the hollow part.

Narrow down Products