5-Phase Stepper Motor PKP Series/CVD Series Fully Closed-Loop Control Type Driver

- DC Input

- Compact Drivers

- Fully Closed-Loop Control

- Submicron High-Precision Positioning

Features | 5-Phase Stepper Motor PKP Series/CVD Series Fully Closed-Loop Control Type Driver

Improved Performance

High Accuracy

Since the step angle of 5-phase PKP Series is at 0.72˚ (high-resolution type at 0.36˚) and the stopping accuracy is at ±0.05˚, highly accurate positioning is possible. In addition, the stop position accuracy controlled by a microstep driver has almost the same high accuracy as that controlled by a full-step driver.

Stopping Accuracy Does Not Get Worse With Microstep

(5-Phase CVD Series Driver + 5-Phase PKP Series Motor)

Low Vibration

As the 5-phase PKP Series has a small basic step angle of 0.72˚ (0.36˚ for high-resolution type), it is lower in vibration and noise than 2-phase stepper motors with a basic step angle of 1.8˚. Also, vibrations and noise can be further reduced through control with the driver of the microstep drive.

Example of 2-Phase Stepper Motor Vibration Characteristics

Example of 5-Phase Stepper Motor Vibration Characteristics

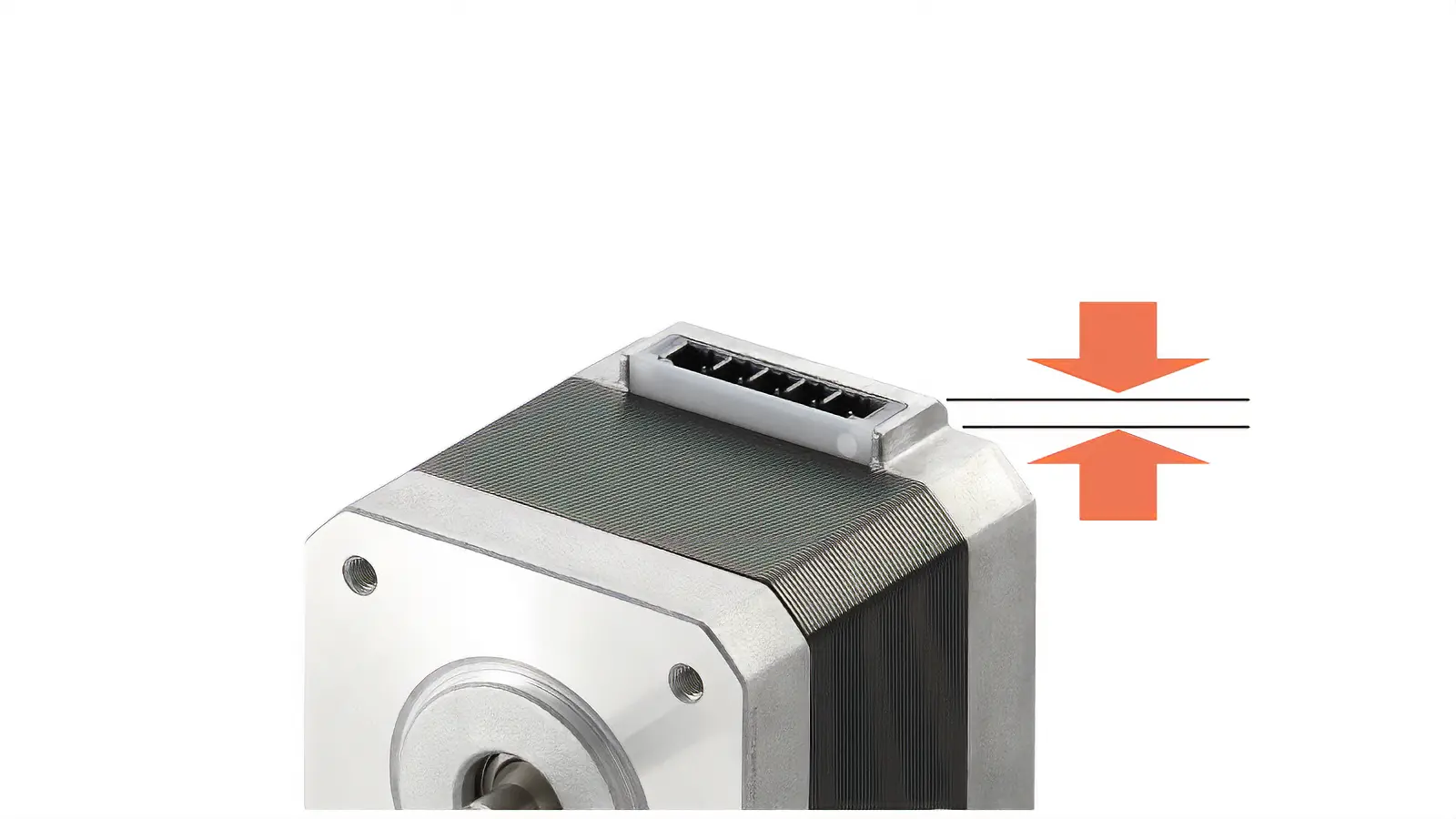

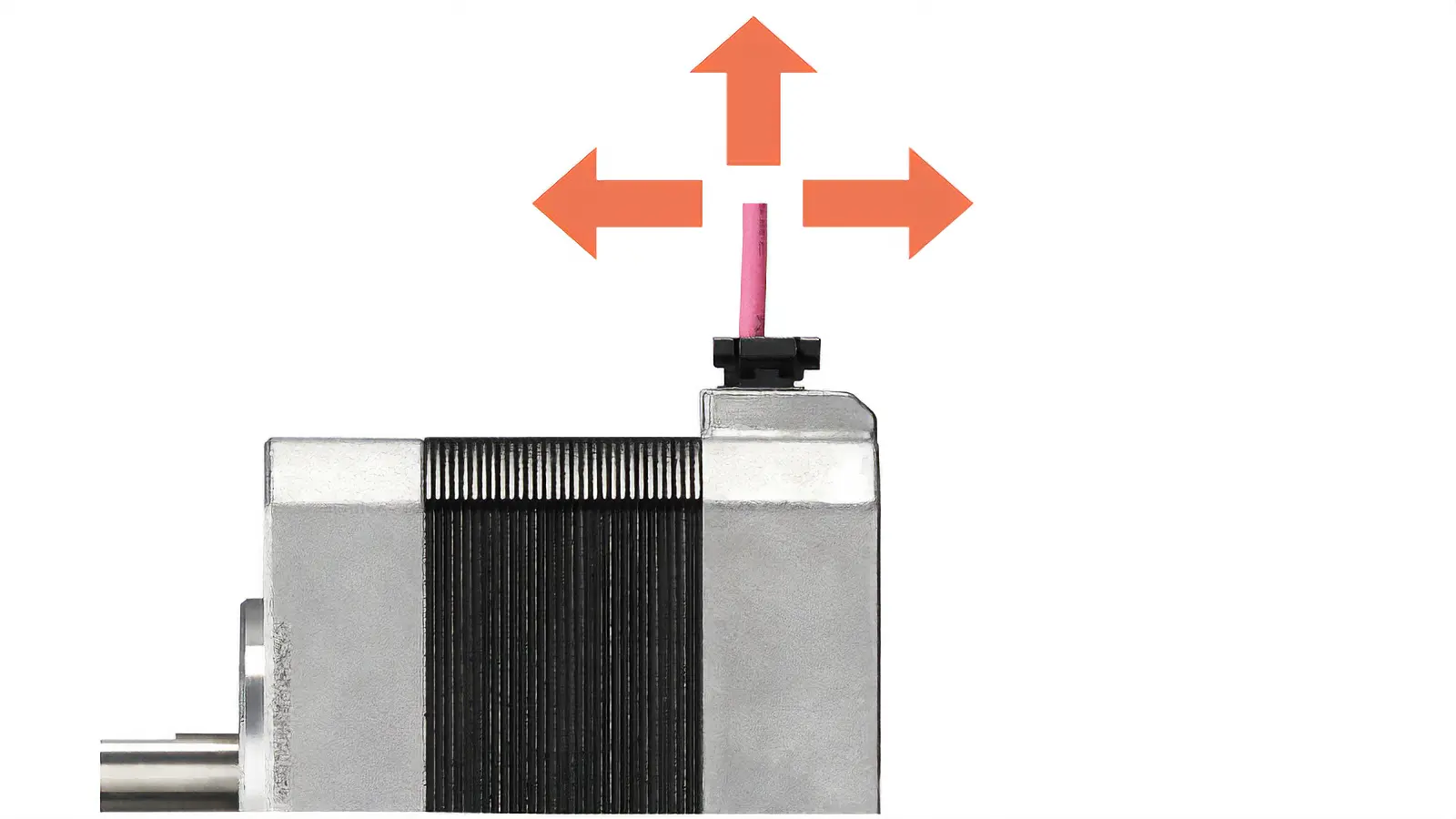

Compact and Flat Connector

The PKP Series uses a compact and flat connector, which lowers the connector's overhang (excluding some products). In addition, flexibility for the motor cable outlet direction has been increased, as outlet direction points upward.

- *For details, refer to the dimensions diagram of each motor.

Driver Features

High Efficiency Design

The CVD Series achieves higher torque by increasing the output current compared to conventional products. The design takes into consideration the reduction of heat generation so that the output current can be increased.

Industry's-Top-Class Compact High Performance Driver

The CVD Series is a small and lightweight driver that helps save space.

Mass: 20~70 g (depending on driver type)

Features of the Fully Closed-Loop Control Type

The fully closed-loop control type can be combined with an external sensor to achieve submicron high-precision positioning. It contributes to the construction of equipment and device designs that require higher-precision control.

Motor Types

5-Phase Stepper Motors

| Series | Type | Frame Size [mm] |

Basic Step Angle [°] |

|---|---|---|---|

| PKP |

Standard

|

28, 42, 60 | 0.72 |

|

High resolution

|

0.36 | ||

|

TS geared

|

42 | 0.024~0.2 | |

| PK |

Standard

|

20, 28, 42, 60 | 0.72 |

Click here for information about 5-Phase Stepper Motor PKP Series

Related Products

Stepper Motor PKP Series/

CVD Series Pulse Input Driver

You want to operate a stepper motor easily by pulse input. This is a motor and pulse input driver that meets such needs. In pursuit of high efficiency, high torque, and low vibration, even better performance has been achieved.

Stepper Motor PKP Series/

CVD Series RS-485 Communication Type Driver

You want to run a stepper motor under Modbus (RTU) control. You want to set data easily on a touch screen. This product combines a motor with a driver that supports RS-485 communication compatible to meet such needs. Up to 31 axes of drivers can be controlled by connecting them to a single host control device.

Narrow down Products