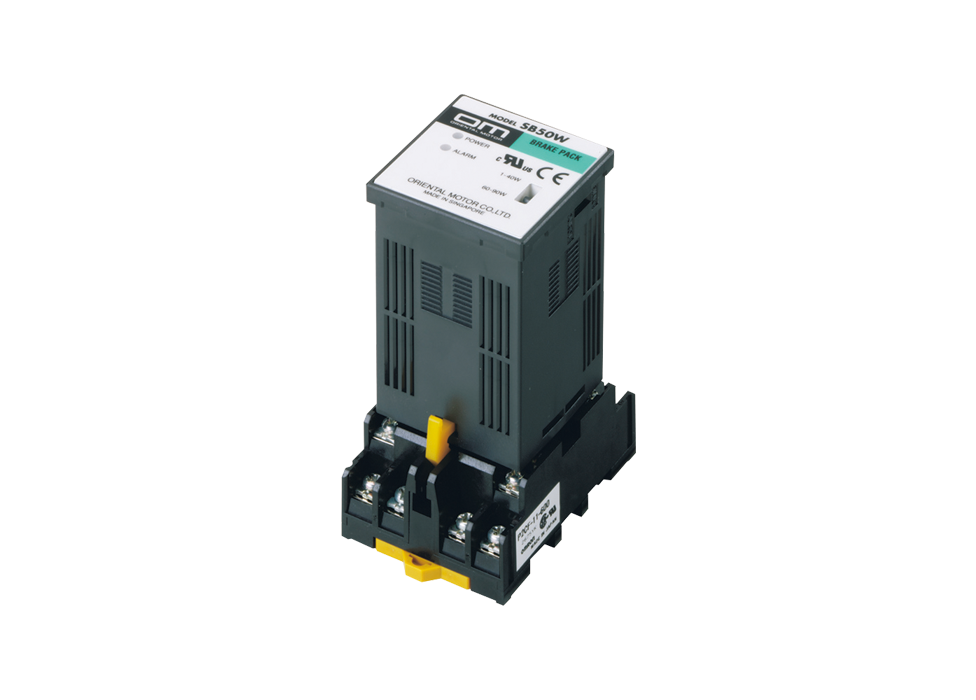

Brake Pack

SB50W

- By Connecting to the Motor, Instantaneous Stopping

- Forward/Reverse Operations and Brake Control are All Possible

- Output Power Compatible with Motors from 1 to 90 W

Features | Brake Pack SB50W

4 Functions Equipped

Equipped with instantaneous stop, bidirectional operation, electromagnetic brake control, and thermal protector open detection function*.

- *Thermal protector open detection function

(Available only when combined with a motor having a built-in thermal protector)

When the motor's thermal protector (overheat protective device) is activated, the SB50W outputs an alarm signal and automatically cuts the power supply to the motor. Even if the temperature drops and the thermal protector comes back on, the motor will not restart automatically. The alarm can be reset with external signals.

Long Life and Easy Wiring

Electronic brakes use electric current, so they do not have parts subject to abrasion like mechanical, electromagnetic brakes and therefore have a long life. They are ideal for applications such as motor inching.

SB50W is a non-contact type, so it does not require a power relay. Its wiring is easy, which reduces the number of times maintenance is required.

Electronic Brake and Electromagnetic Brake Interlocking

SB50W can be used in combination with an electromagnetic brake motor to interlock the electronic brake with the electromagnetic brake and automatically hold the load after an instantaneous stop. Ideal for applications where load holding is required after an instantaneous stop.

Supports Wide Voltage (100-230 V)

The SB50W can handle single-phase 100 VAC~230 VAC ±10 % in a single unit, covering the world's major voltage specifications. It can be used in accordance with the power supply voltage of the applicable motor.

Compatible With 1 W~90 W Motors

It can be used in combination with induction motors, reversible motors, electromagnetic brake motors, and watertight, dust-resistant motors with motor output power of 1 W~90 W.

Can Switch Sink/Source Logic

I/O circuits can be switched between sink and source. You can switch between them as needed.

Product Line

| Combination Motor | Series | Type | Upper Row: Motor Frame Size (mm)/Lower Row: Output Power (W) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 42 | 60 | 70 | 80 | 90 | |||||

| 1 | 6 | 15 | 25 | 40 | 60 (55) |

90 (85) |

|||

| Induction Motor | World K Series* | Lead Wire | ● | ● | ● | ● | ● | ● | ● |

| With terminal box | – | ● | ● | ● | ● | ● | ● | ||

| With IP65 terminal box | – | ● | – | – | – | – | – | ||

| Reversible Motor | World K Series | Lead Wire | ● | ● | ● | ● | ● | ● | ● |

| With terminal box | – | ● | – | ● | ● | ● | ● | ||

| Electromagnetic Brake Motor | World K Series | Lead Wire | – | ● | ● | ● | ● | – | – |

| With cable | – | – | – | – | – | ● | ● | ||

| With IP65 terminal box | – | ● | – | – | – | – | – | ||

| Watertight, Dust-Resistant Motors | FPW Series | – | – | – | ● | ● | ● | ● | |

- *Excluding 2 poles type.

Note

- Cannot be used with three-phase motors.

Characteristics of Brake Pack

How to Read Braking Characteristics (Reference values)

The brake pack has stable braking characteristics that bring the motor to an instantaneous stop. Braking characteristics are represented by a braking curve that shows the value of overrun relative to the load inertia.

The braking time is 4 n/f seconds or less.

n: Overrun [revolutions], f: Power supply frequency [Hz]

For example, when using a 25 W induction motor and SB50W to stop a load with inertia of J = 0.25 [× 10-4 kg·m2], the overrun is about 1.25 revolutions at a power supply frequency of 50 Hz, and the braking time is about 0.1 seconds. If the gearhead is used for deceleration, convert the inertia of the gearhead shaft to that of the motor shaft to see the braking characteristics curve.

To convert the gearhead shaft inertia to the motor shaft, use the following formula.

- JM

- Load inertia converted to motor shaft

- JG

- Load inertia at gearhead axis

- i

- Gearhead gear ratio

Example of Brake Pack Braking Characteristics

The braking characteristics curve shows the average value of the overruns, so it should be viewed as a reference value.

Stopping Accuracy of Brake Pack

The following figure shows the stopping position error (stop position variation) when braking is applied to the motor using the brake pack. This is the distribution of overruns when braking is repeated 500 times under the same conditions. The reason for this variation is that there is a time lag of up to 1 cycle (power supply frequency) due to the power-supply phase when the switch is switched to perform braking, and there are variations in the initial braking force. The lowered middle in the figure below is attributable to the slot position of the stator and rotor.

Fuse Capacitance

When the brake pack is used to perform an instantaneous stop of the motor, a large braking current flows into the motor for about 0.4 seconds. Therefore, when connecting a fuse to the power supply line, provide a fuse of appropriate capacitance, while referring to the braking current value of the motor used (listed in the "Applicable Motor Specifications" of each brake pack).

Other Brake Motors

In addition to brake packs, Oriental Motor also offer brake motors to suit your application.

Other Brake Motor Options

Select by Stopping Accuracy

- For low-speed synchronous motors, the motor can be stopped within 10˚ of stopping accuracy just by turning off the power supply.

Select by Frequency of Use

Note

- The operating cycle values are calculated based on brake responsiveness. This value is the maximum value, so it may not be possible to perform a continuous braking operation at this frequency.

- When actually using the product, consider the temperature rise of the motor and use it under conditions where the surface temperature of the motor case is max. 90 °C.

- The low-speed synchronous motor is capable of starting, stopping, and bidirectional operation at 1.5 cycles of the power supply frequency within the motor's permissible load inertia.

Narrow down Products