Stepper Motors PKP Series/PK Series (2-Phase)

PKP243MU09M-L

Motor

| Product Classification | Product Name | List Price | Shipping Date |

|---|---|---|---|

| Motor | PKP243MU09M-L | Rs. 12,400 | Product to be Discontinued (30.9.2026 order deadline) |

- *Please contact us regarding purchasing of product.

- *Product will be discontinued on 31.3.2027. Please place your order before the order deadline.

Included

- Motor: Lead Wires with Connector, Varistor, Operating Manual

Specifications

Data Download

Other Specifications

General Specifications

| Item | Specification | |

|---|---|---|

| Operating Environment (when operating) |

Ambient Temperature | -10~+50 °C (Non-freezing) Flat Harmonic Gearhead Type is 0~+40 °C (Non-freezing) |

| Ambient Humidity | 85 % max. (Non-condensing) | |

| Atmosphere | No corrosive gases or dust No exposure to water, oil or other liquids. | |

| Temperature Rise | Winding temperature rise 80 °C max. (Based on Oriental Motor's internal measurement conditions) | |

| Stop position accuracy*1 | ±3 arc minute (±0.05˚) [PKP21□, PKP242, PKP262is ±5 arcmin (±0.083°), PK26□J, PK26□JDis ±2 arcmin (±0.034°)] |

|

| Shaft Runout | 0.05 T.I.R. (mm) *4 *5 | |

| Radial Play*2 | 0.025 mm Max. (Load 5 N) [PKP203 Load 2.5 N] |

|

| Axial Play*3 | 0.075 mm Max (Load 10 N) [PKP203・PKP21□ Load 1 N, PKP22□, PKP242, PKP262 Load 2.5 N] |

|

| Concentricity of Installation Pilot to the Shaft | 0.075 T.I.R. (mm)*4 | |

| Perpendicularity of mounting surface to the shaft | 0.075 T.I.R. (mm)*4 | |

- *1

- This is the value at full step and no load (Varies depending on the size of the load).

- *2

- Radial Play: Displacement in shaft position in the radial direction when a 5 N load (PKP203 Load 2.5 N) is applied perpendicular to the tip of the motor shaft.

- *3

- Axial Play: Displacement in shaft position in the axial direction when a 10 N load (PKP203, PKP21□ Load 1 N, PKP22□, PKP242, PKP262 Load 2.5 N) is applied to the motor shaft in the axial direction.

- *4

- T.I.R. (Total Indicator Reading): The total dial gauge reading when the measurement section is rotated 1 revolution centered on the reference axis center.

- *5

- PKP244P has 0.025 T.I.R. (mm)

Electromagnetic Brake Specifications

| Product Name | PKP22 | PKP23 and PKP24 | PKP26 | PKP26□M2 |

|---|---|---|---|---|

| Type | Power off activated type | |||

| Power Supply Voltage | 24 VDC ±5% | |||

| Power Supply Current [A] | 0.05 | 0.07 | 0.23 | 0.18 |

| Static Friction Torque [N·m] | 0.08 | 0.3 | 1.5 | 0.8 |

| Brake Activation Time [ms] | 20* | |||

| Brake Release Time [ms] | 50* | |||

| Time Rating | Continuous | |||

- *This is the value when the included varistor is used. [Recommended Varistor: Z15D121 (SEMITEC Corporation)]

Rotation Direction

This indicates the rotation direction when viewed from the output shaft side.

The rotation direction of the gearhead output shaft relative to the standard type motor output shaft varies depending on the gear type and gear ratio. Please check the following table.

| Type | Gear Ratio | Rotation Direction as Viewed From the Motor Output Shaft Side |

|---|---|---|

| TS Geared Type | 3.6, 7.2, 10 | Same direction |

| 20, 30 | Opposite direction | |

| TH Geared Type Frame size 28 mm |

7.2, 10 | Opposite direction |

| 20, 30 | Same direction | |

| TH Geared Type Frame size 42 mm, 60 mm, 90 mm |

3.6, 7.2, 10 | Same direction |

| 20, 30 | Opposite direction | |

| SH Geared Type Frame size 28 mm |

7.2, 36 | Same direction |

| 9, 10, 18 | Opposite direction | |

| SH Geared Type Frame size 42 mm, 60 mm |

3.6, 7.2, 9, 10 | Same direction |

| 18, 36 | Opposite direction | |

| SH Geared Type Frame size 90 mm |

3.6, 7.2, 9, 10, 18 | Same direction |

| 36 | Opposite direction | |

| CS Geared Type | 5, 10, 15, 20 | Same direction |

|

FC Geared Type PS Geared Type PN Geared Type HPG Geared Type |

Overall gear ratio | Same direction |

| Harmonic Geared Type | 50, 100 | Opposite direction |

Permissible Radial Load and Permissible Axial Load

Unit: N

| Type | Motor Frame Size | Motor Product Name | Gear Ratio | Permissible Radial Load | Permissible Axial Load | ||||

|---|---|---|---|---|---|---|---|---|---|

| Distance From Shaft End [mm] | |||||||||

| 0 | 5 | 10 | 15 | 20 | |||||

| High-Resolution Type / High-Resolution Type With Encoder / High-Resolution Type With electromagnetic brake |

42 mm | PKP243, PKP244, PKP544, PKP546 | - | 20 | 25 | 34 | 52 | - | 10 |

| 56.4 mm | PKP264, PKP266, PKP268 | 54 | 67 | 89 | 130 | - | 20 | ||

| 60 mm | PKP564, PKP566, PKP569 | 90 | 100 | 130 | 180 | 270 | 20 | ||

| Standard Type / Standard Type With Encoder / Standard Type With electromagnetic brake |

20 mm | PKP213, PKP214 | 12 | 15 | - | - | - | 3 | |

| 28 mm | PKP223, PKP224, PKP225, PKP523, PKP525 |

25 | 34 | 52 | - | - | 5 | ||

| 35 mm | PKP233, PKP235 | 20 | 25 | 34 | 52 | - | 10 | ||

| 42 mm | PKP243, PKP244, PKP245, PKP246, PKP544, PKP546 |

20 | 25 | 34 | 52 | - | 10 | ||

| 50 mm | PK256, PK258 | 54 | 67 | 89 | 130 | - | 20 | ||

| 56.4 mm | PKP264, PKP266, PKP268 | 61 | 73 | 90 | 110 | 160 | 20 | ||

| 60 mm | PKP564, PKP566, PKP569 | 63 | 75 | 95 | 130 | 190 | 20 | ||

| PKP262 | 20 | 25 | 34 | - | - | 5 | |||

| PK264J, PK266J, PK267J, PK269J | 50 | 60 | 75 | 100 | 150 | 20 | |||

| 85 mm | PK296, PK299, PK2913, PKP296, PKP299, PKP2913 |

260 | 290 | 340 | 390 | 480 | 60 | ||

| SH Geared Type | 28 mm | PKP223 | 7.2, 9, 10, 18, 36 | 15 | 17 | 20 | 23 | - | 10 |

| 42 mm | PKP243 | 3.6, 7.2, 9, 10, 18, 36 | 10 | 15 | 20 | 30 | - | 15 | |

| 60 mm | PKP264 | 3.6, 7.2, 9, 10 | 30 | 40 | 50 | 60 | 70 | 30 | |

| 18, 36 | 80 | 100 | 120 | 140 | 160 | ||||

| 90 mm | PK296 | 3.6, 7.2, 9, 10, 18, 36 | 220 | 250 | 300 | 350 | 400 | 100 | |

Inner Wiring Diagram of Motor

Unipolar (6 lead wires)

Unipolar (5 lead wires)

Bipolar (4 lead wires)

Standards

Hazardous Substances

The product does not contain any substances (10 substances) exceeding the regulation values of the RoHS Directive (2011/65/EU, 2015/863/EU).

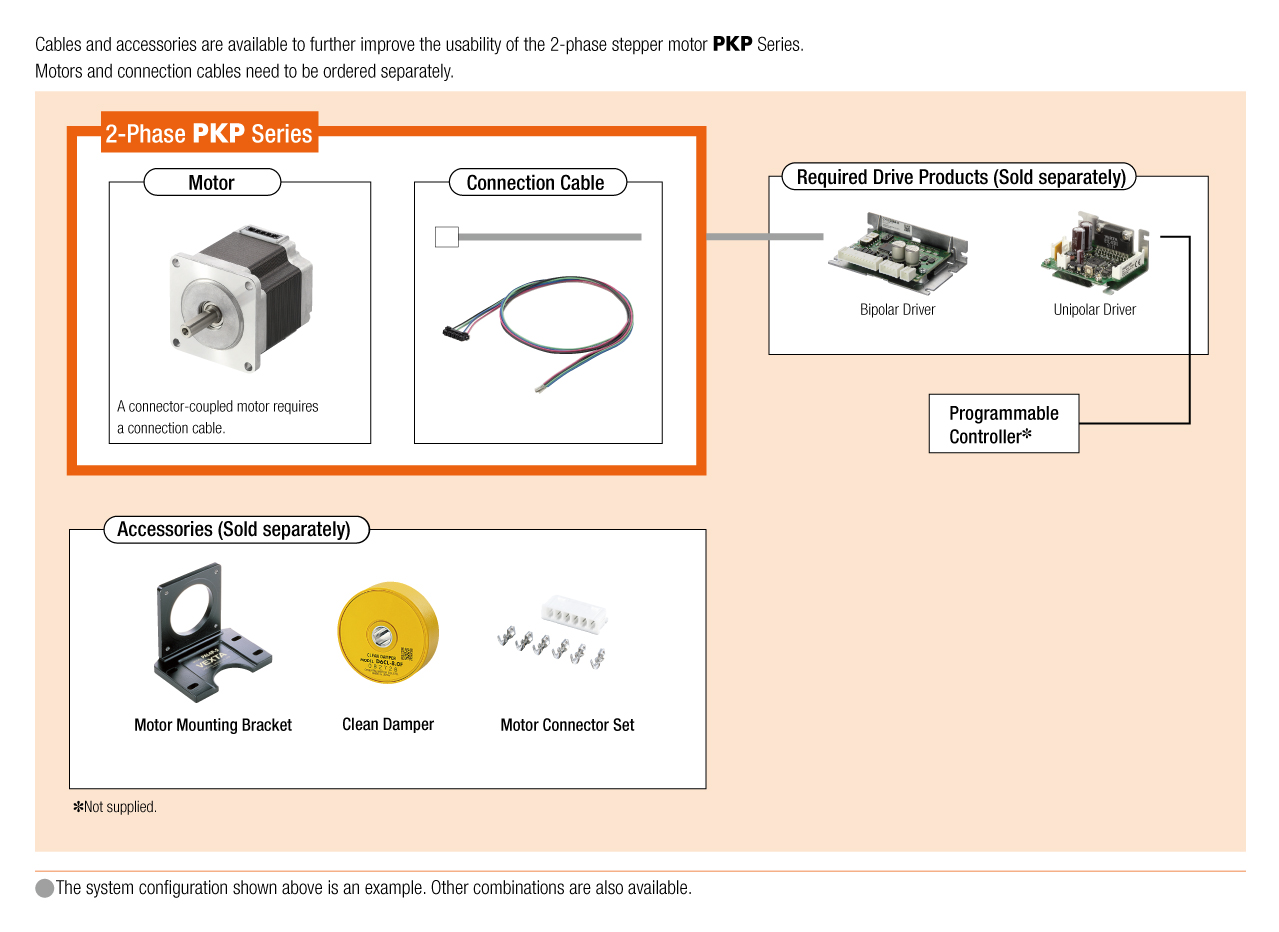

System Configuration

Cables and Accessories

close