Article on in-house robots

|

|

Demand for robots has been increasing in recent years as factories seek to improve productivity and save labor through equipment automation. At the same time, however, commercially available industrial robots are large and difficult to install on production lines. Moreover, their high cost often poses an obstacle to their adoption. |

-Reduce Deployment Costs and Maximize Cost-Effectiveness-

Installable on Existing Production Lines -Compact Design for Limited Spaces-

Intuitive Control, Easy Creation of Robots

-Achieve Labor Savings and Factory Automation with Facilitate Deployment-

Intuitive Control ,Easy Creation of Robots -Achieve Labor Savings and Factory Automation with Facilitate Deployment-

Robots use multiple motors, resulting in many design burdens, such as how to mechanically design gears and ball screws, how to arrange sensors, and how to design the wiring. To design a multi-axis robot, in-house manufacturers would have to face many programming and control hurdles. To overcome these challenges, Oriental Motor offers a lineup of controllers that are easy to program and control, as well as motors and actuators that reduce design burdens.

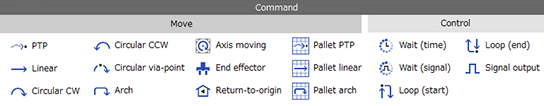

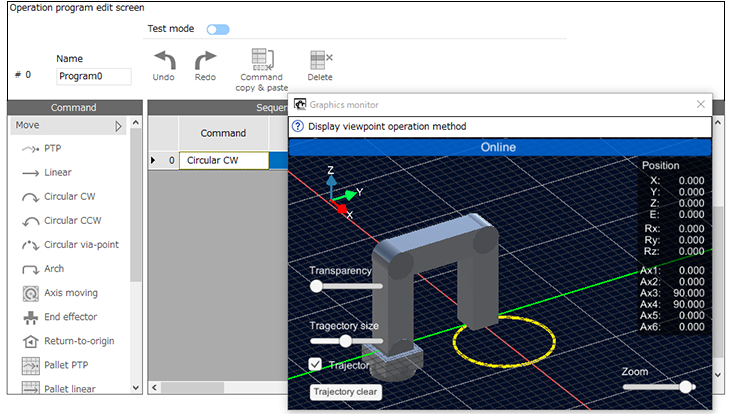

MRC01 makes it easy to control robots

We have developed a robot controller MRC01. The dedicated programming software MRC Studio enables even inexperienced robot designers to quickly program and control robots. MRC01 reduces programming and control hurdles and makes it easy to start producing robots in-house.

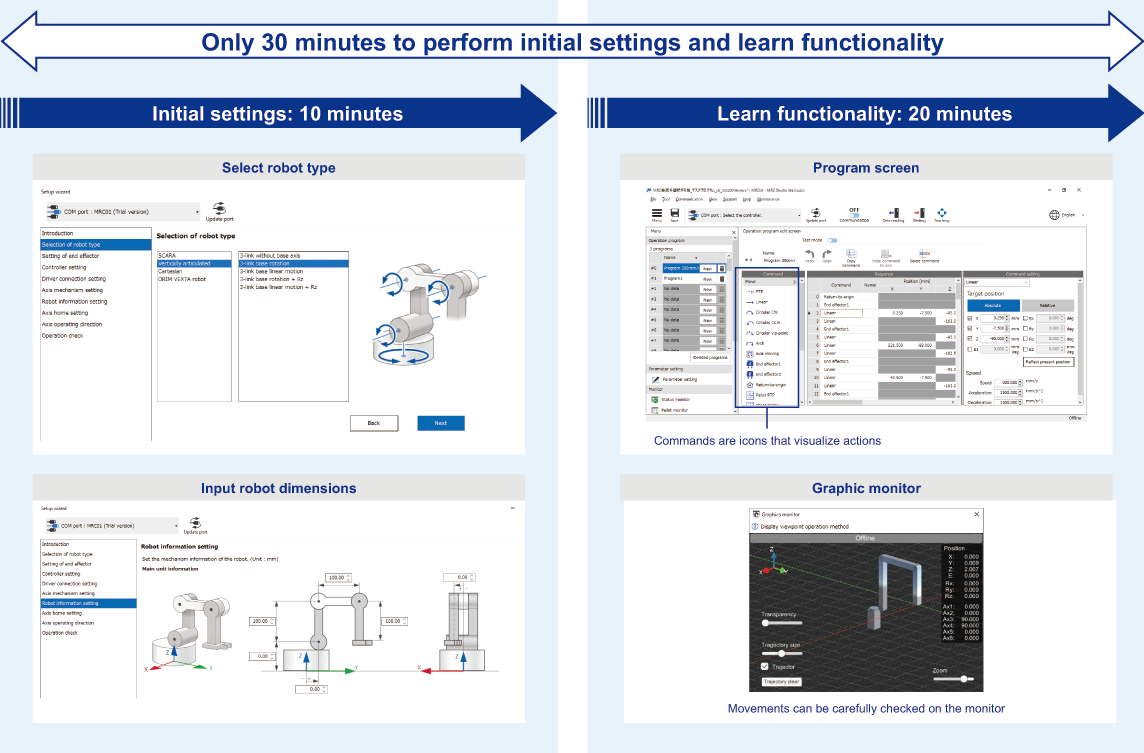

Learning curve of only 30 minutes

Even inexperienced robot designers can master MRC Studio in about 30 minutes. This includes 10 minutes for initial setup and 20 minutes for learning software functionality.

|

αSTEP AZ Series reduces design burdens

Many different parts are needed to manufacture a robot, including motors, gears, ball screws, arms, and robot grippers. As the number of parts increases, so does the burden of designing and managing them. Moreover, if the type of motor needs to be changed due to a different usage environment, the use of the robot would have to be learned all over again. The AZ Series reduces these burdens.

|

αSTEP AZ Series reduces design burdens

Many different parts are needed to manufacture a robot, including motors, gears, ball screws, arms, and robot grippers. As the number of parts increases, so does the burden of designing and managing them. Moreover, if the type of motor needs to be changed due to a different usage environment, the use of the robot would have to be learned all over again. The AZ Series reduces these burdens.

Click here to learn more about the AZ Series

Offers a wide range of variations to reduce the burden of learning how to use robots

The AZ Series includes a complete lineup of motors and mechanical components such as gears, sliders, tables, and grippers. This reduces the burden of the mechanical design required of gears, ball screws, and other components.

Furthermore, if all moving robot parts are AZ Series products, not only can usage be standardized, but the commonality of parts such as cables and drivers reduces the burden of parts procurement.

|

Sensorless design reduces the burden of sensor wiring and procurement

The AZ Series comes with a battery-less multi-turn absolute sensor that retains position information even when powered off. This reduces the burden of designing and arranging the wiring of the home sensor and limit sensor.

|

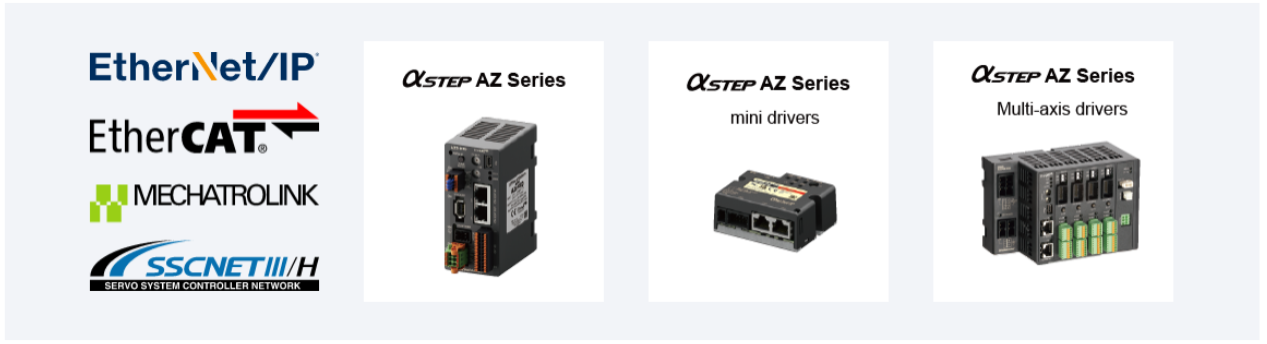

AZ Series products work with other company controllers

When designing the control operations of equipment, it may be necessary to use controllers other than MRC01 products. Since each controller has different communication specifications, it is necessary to use a motor that matches these specifications. The AZ Series provides a lineup of drivers that support various industrial networks, including EtherNet/IP, EtherCAT, PROFINET, SSCNETIII/H, and MECHATROLINK-III. Even when using the robot controllers of other companies, it is still possible to take advantage of AZ Series variations and sensorless design features.

|

- *Harmonic Planetary and Harmonic Drive are registered trademarks of Harmonic Drive Systems Inc.

- *EtherCAT is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

*EtherCAT is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany. - *EtherNet/IP is a trademark of ODVA.

- *MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

- *SSCNETIII/H is a registered trademark of Mitsubishi Electric Corporation.