Article on in-house robots

|

|

Demand for robots has been increasing in recent years as factories seek to improve productivity and save labor through equipment automation. At the same time, however, commercially available industrial robots are large and difficult to install on production lines. Moreover, their high cost often poses an obstacle to their adoption. |

-Reduce Deployment Costs and Maximize Cost-Effectiveness-

Installable on Existing Production Lines -Compact Design for Limited Spaces-

Intuitive Control, Easy Creation of Robots

-Achieve Labor Savings and Factory Automation with Facilitate Deployment-

Installable on Existing Production Lines -Compact Design for Limited Spaces-

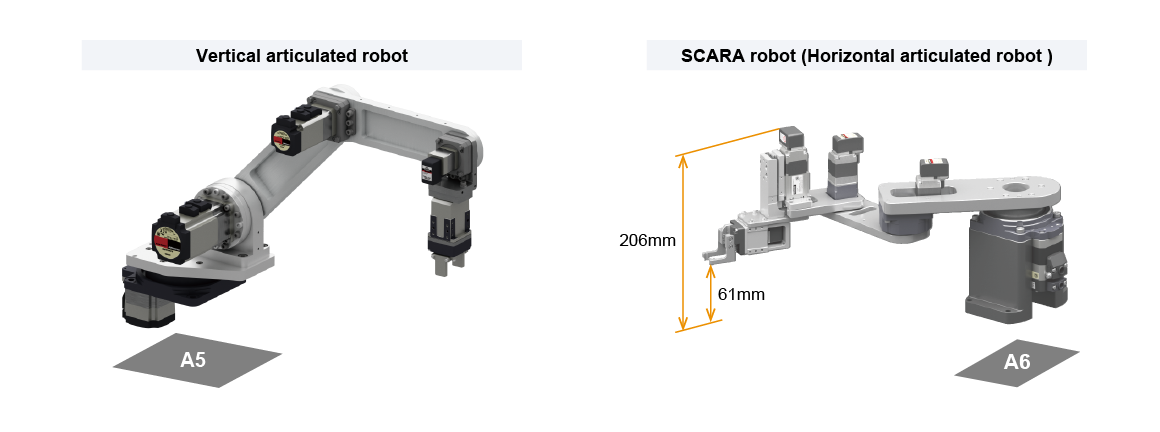

Many commercially available industrial robots are large, making them difficult to install in limited spaces. Production lines would need to be reconstructed to accommodate the robots. However, the costs and labor required to do this would not be feasible when only automating simple tasks. In contrast, companies can design in-house robots to meet their needs, including small tabletop vertical articulated robots and low-floor transportation SCARA robots. In-house robots are easy to install on existing production lines.

Factory production lines optimized by in-house robot manufacturing

If you design an in-house robot to meet your company needs, it can be flexibly manufactured according to the actual space and operation specifications, allowing you to smoothly automate tasks in your factory. For example, the installation space for a vertical articulated robot is approximately 130 x 170 mm. This footprint is smaller than the size of A5 paper, enabling it to be installed in a space-efficient manner.

|

Click here to see examples of in-house manufacturing of SCARA robots (Horizontal articulated robots)

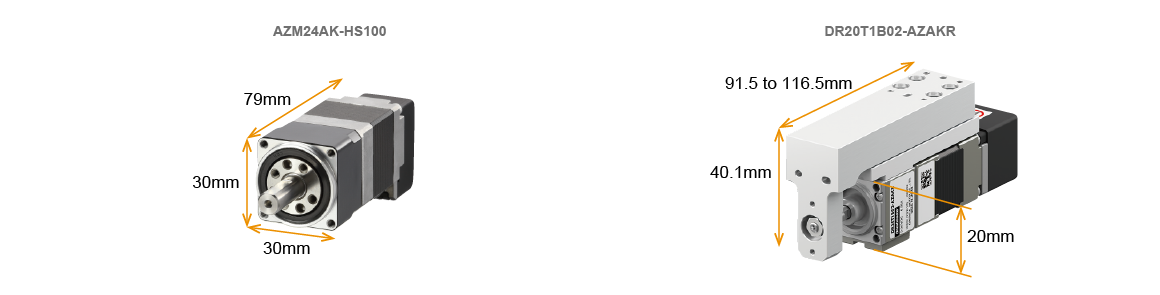

Production of compact robots using small motors

When manufacturing robots for limited spaces in-house, all the parts must be miniaturized, including the motor. Oriental Motor offers an extensive lineup of compactly designed motors and linear and rotary type actuators, such as those in our αSTEP AZ Series. Manufacturing robots in-house enables them to be smaller.

|

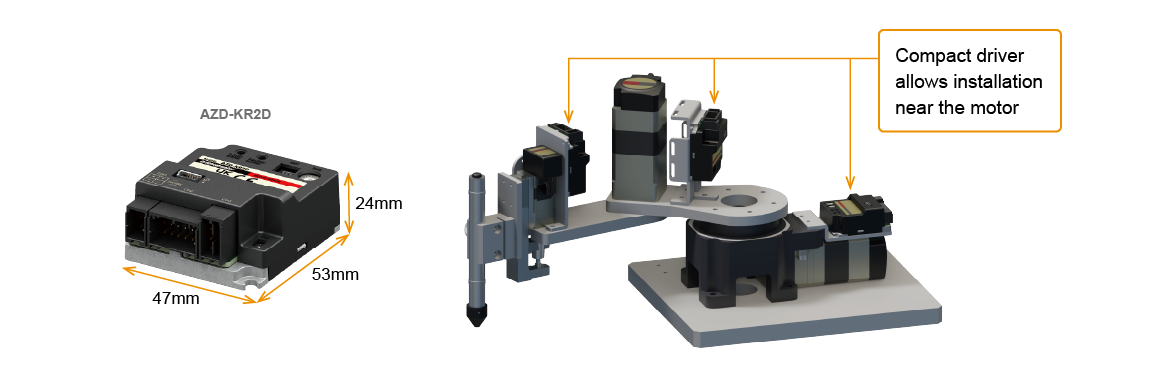

Compact driver that can be positioned with a high degree of flexibility

Driver size must not be overlooked when creating small in-house robots. Compact drivers can be installed in the smallest of spaces and can be flexibly positioned without being constrained by the location of the power distribution panel. For example, if the driver is installed right next to the motor, less motor cable will be needed. This creates a cleaner production site with less wiring.

Click here to learn more about AZ Series mini drivers