Article on in-house robots

Supporting In-house Production of Robots with Our Products and Services

| Publication of Case Studies on In-house Robots and Release of Robot Controller Lineup | |

|

Many manufacturers are interested in the many benefits of automating transportation and basic tasks. However, it is also clear that the deployment of robots requires a large initial investment and sufficient installation space, two things that are often not feasible for companies. This is why in-house production of robots has been gaining attention. Oriental Motor has published case studies on in-house robot production, has released a lineup of robot controllers that can be used with our freely-provided control software. We asked Hiroshi Yamakoshi, Head of the Product Planning Section in the Product Planning Department of the Sales Division, to give us an overview of Oriental Motors in-house robots. |

Expanding in-house production of “robots tailored to the actual situation of the company”

It is currently a major trend in the manufacturing industry to automate transportation and basic tasks conventionally performed by humans. Many companies are interested in deploying transportation and working robots because of their significant benefits. However, it has become apparent that these robots come with some challenges.

For example, an AMR (autonomous transport robot) is generally expensive, with a unit costing about 1.5 million yen, and a highly functional work robot exceeding 3 million yen. Furthermore, since system integration by system integrators is required for actual introduction, the initial investment exceeds 10 million yen. “Since it is expensive, some companies are wondering whether it is worthwhile to reduce the number of workers and invest in it, or whether it will be cheaper for people to do the work. is the reality,” says Yamakoshi.

In the case of articulated robots that do basic tasks conventionally performed by humans, if a company deploys a general-purpose robot, it needs to redesign higher-level systems and line configurations, and make room for installation. In the case of automation in very confined spaces, it is often difficult to find robots to fit in those spaces, and even if such robots are available, they may come with overly complicated specifications. Either way, it is often not worth the cost and effort of deploying robots. As a result, automation is often foregone.

This is why in-house production of robots customized to company needs has been gaining attention. There are increasing efforts to produce in-house AGVs (automated guided vehicles) and install working robots for conveyors of AGV and AMR loaders and unloaders, SCARA, gantry, and vertical articulated applications, as well as to manufacture in-house robots for confined spaces. Yamakoshi noted, “At exhibitions, our robots that use our proprietary built-in motors and drivers are attracting lots of attention. We have received many inquiries about how to produce them in-house. It’s cheaper to manufacture robots in-house. This also has the advantage of enabling in-house maintenance.”

On the other hand, some customers say that even if they can produce mechanical robots, it is still difficult to control and program the robots during actual usage. As a result, they are not ready to move forward with full-scale in-house production. It is against this backdrop that we took initiatives to respond to the needs of customers who wanted to produce robots in-house.

Hiroshi Yamakoshi - Manager, Product Planning Section,

Product Planning Department, Oriental Motor Sales Headquarters

Full Lineup of Products including Motors, Robot Controllers, and Programming Software

The first and most important step in producing in-house robots is the selection of motors. To facilitate this, Oriental Motor offers a complete lineup of control motors, gears, linear and rotary actuators, and other control motors, such as products in its αSTEP AZ Series that use battery-less absolute sensors.

To help customers select the most suitable motors, our sales activities include offering a motor selection service free of charge to suggest motors that correspond to the drive and torque specifications of their application. Yamakoshi explained, “For example, in the case of a vertical articulated robot, if customers provide us with information on the arm length, load, and other specifications, we will perform the necessary calculations and suggest an applicable motor.”

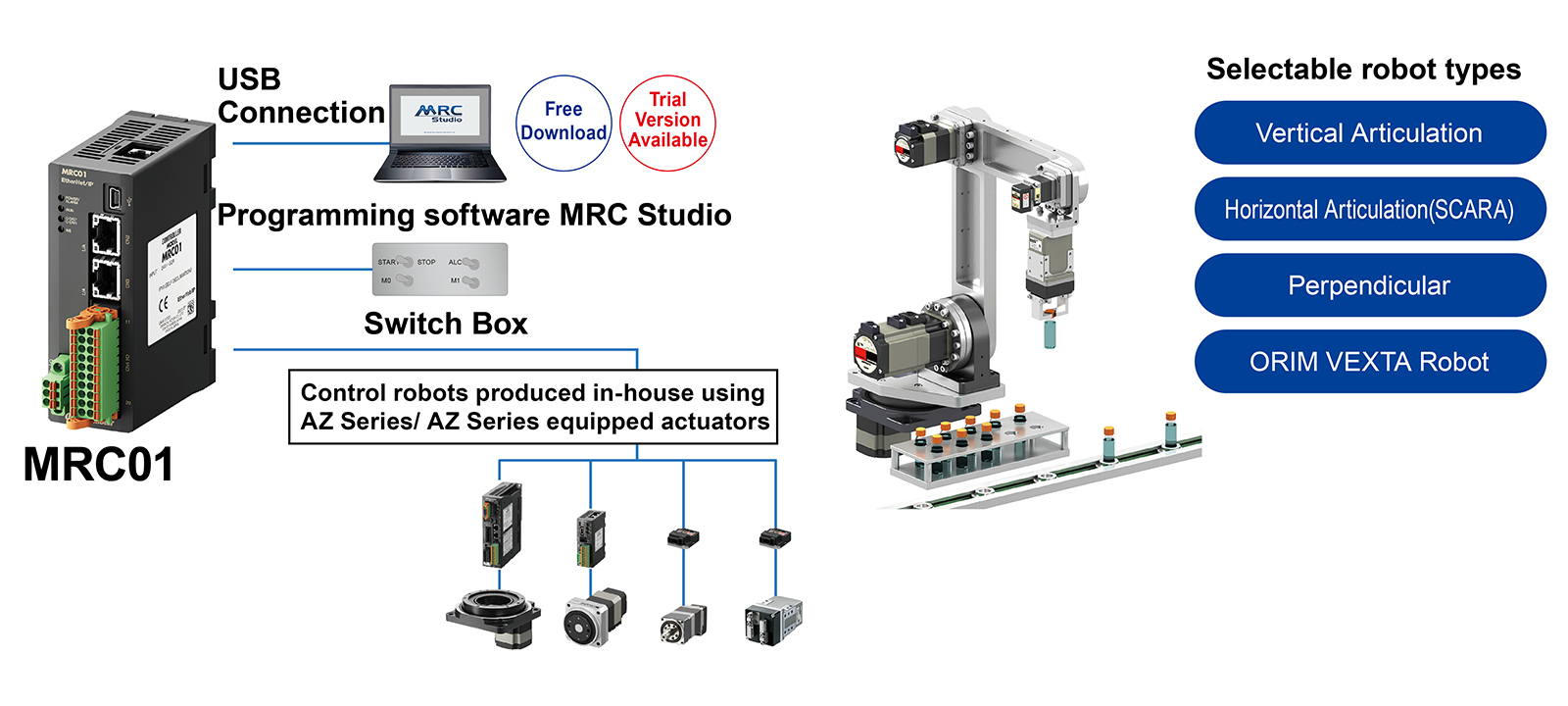

Although Oriental Motor is primarily a motor manufacturer, we also offer MRC01 robot controllers and MRC Studio, a free dedicated configuration and programming software package, to help meet the programming needs of customers.

The MRC01 is a robot controller that facilitates the deployment and control of in-house robots in three steps, including initial settings, operation programming, and operation check (see the diagram).

By simply connecting the MRC01 with a PLC, customers can deploy additional in-house robots without making major changes to the control system of existing equipment. A simple sequence can be run using direct I/O without a host device. The MRC01 can be connected to AZ Series products and AZ Series mounted linear and rotary actuators. In addition, it can control a wide range of robot types, including vertical articulated types, horizontal articulated (SCARA) types, gantry types, and ORIM VEXTA robots manufactured by our affiliated companies.

MRC Studio is a dedicated configuration and programming software package that comes with an intuitive user interface. It is designed for beginners and allows them to configure and program robots using a wizard without specialized knowledge. Yamakoshi commented, “It’s very popular because its free to download and easy to set up and use.” Although it has been less than a year since we launched MRC Studio, it is already being adopted on several mass production lines. For example, one medical device manufacturer evaluated our products and decided to deploy gantry robots programmed with MRC Studio on its workpiece transportation line.

Publication of Case Studies on Producing Deployable In-house Robots for Less than 1 Million Yen

In recent years, we have been receiving an increasing number of inquiries from customers who have no experience producing in-house robots, asking for details on feasibility, system configurations, prices, and sizes. Therefore, we have posted in-house production examples on the Oriental Motor website. These examples include SCARA robots for inter-process transportation (horizontal articulated robots), AGVs, screw fasteners, work processing equipment (gantry robots and lifting and turning modules), work lifting and lowering equipment, and various parts supply equipment that are used in actual factories. Each example describes the structure and system configuration of the robots and the key points of product selection. Yamakoshi explained, “All of these robots, including the required electrical components, can be installed for less than 1 million yen. We have published information on drawings, system configurations, and prices. Some customers are hesitant to make the initial investment, but since the price is less than 1 million yen, they often want to give it a try.”

Please contact Oriental Motor if your company is looking for low-cost automation of simple movements, such as transporting workpieces small distances between processes. We offer products and services that enable the realization of small and easily controllable in-house robots.