Modular automation compatible products that support future automation

Modular Automation Products to Help Automate Future Technologies

| Aiming to Realize Layout-Free Automation Equipment and Lines | |

|

There is increasing demand for systems that can respond to changes in manufacturing, such as labor shortages and shortened product life cycles. As a result, companies are accelerating their efforts to use automation as a substitute for human workers and to achieve production line modularization. Oriental Motor has developed product lines that contribute to automation as “Modular Automation Products” and has begun to market them to customers. We asked Hiroshi Yamakoshi, Head of the Product Planning Section in the Product Planning Department of the Sales Division at Oriental Motor, to give us an overview of Modular automation products. |

Keys to Automation: “Automation as a Substitute for Human Workers” and “Production Line Modularization”

The manufacturing industry is currently facing challenges because of labor shortages due to the decline in the working population, shortened product life cycles, high-mix low-volume production, and production customized to the specifications of each country due to global expansion. In recent years, the manufacturing industry has been faced with the urgent task of acquiring the flexibility to cope with such challenges. Major trends include using “automation as a substitute for human workers” and achieving “production line modularization.”

“Automation as a substitute for human workers” aims to eliminate labor shortages and improve productivity by automating basic tasks such as supplying parts to production lines and transporting workpieces between processes, things that have conventionally been performed by humans.

Yamakoshi explained, “Some examples include automation of transportation carts using AGVs (automated guided vehicles) and AMRs (autonomous transport robots), as well as automation of transshipment, loading, and unloading. In addition, space-saving robots are used to automate detailed tasks that have conventionally been performed by humans, such as grabbing and processing.”

The manufacturing industry also faces the need to develop efficient production lines for high-mix, low-volume production in order to respond quickly to changes in the market, and to establish lines customized to the markets of each country and region undergoing global expansion. Conventional fixed production lines are not flexible enough to cope with these challenges. In response, companies are working on “modularization” of production lines, in which equipment is separated for each process and reconfigured according to manufacturing circumstances.

Modularization is spreading across a wide range of fields, including the pharmaceutical and consumer electronics industries. Yamakoshi noted, “In the future, I think that modularized production lines will be separated from each other, and AGVs and AMRs will be used to automatically transport workpieces between them.”

As such, it is not difficult to imagine the development of automation equipment and lines with “adjustable layouts” and flexible automation in order to respond to these challenges.

Hiroshi Yamakoshi - Manager, Product Planning Section,

Product Planning Department, Oriental Motor Sales Headquarters

Providing Modular Automation Products that Support “Layout-Free Automation”

Oriental Motor has developed product lines that support these needs as “Modular Automation Products” and has begun to market them to customers. These product lines are based on the concept of being battery-driven (DC input), compact, and lightweight, and are ideal for mounting on self-running devices and modularized devices. Through layout-free automation, we are contributing to the elimination of labor shortages, improving productivity, saving space, and producing high-mix, low-volume products.

In general, the voltage of batteries increases slightly when fully charged, and then decreases when discharged. Modular automation products are capable of responding to these fluctuations. The drivers of these products are also very small and lightweight, enabling them to be integrated into the confined spaces in equipment even when a control panel is not available.

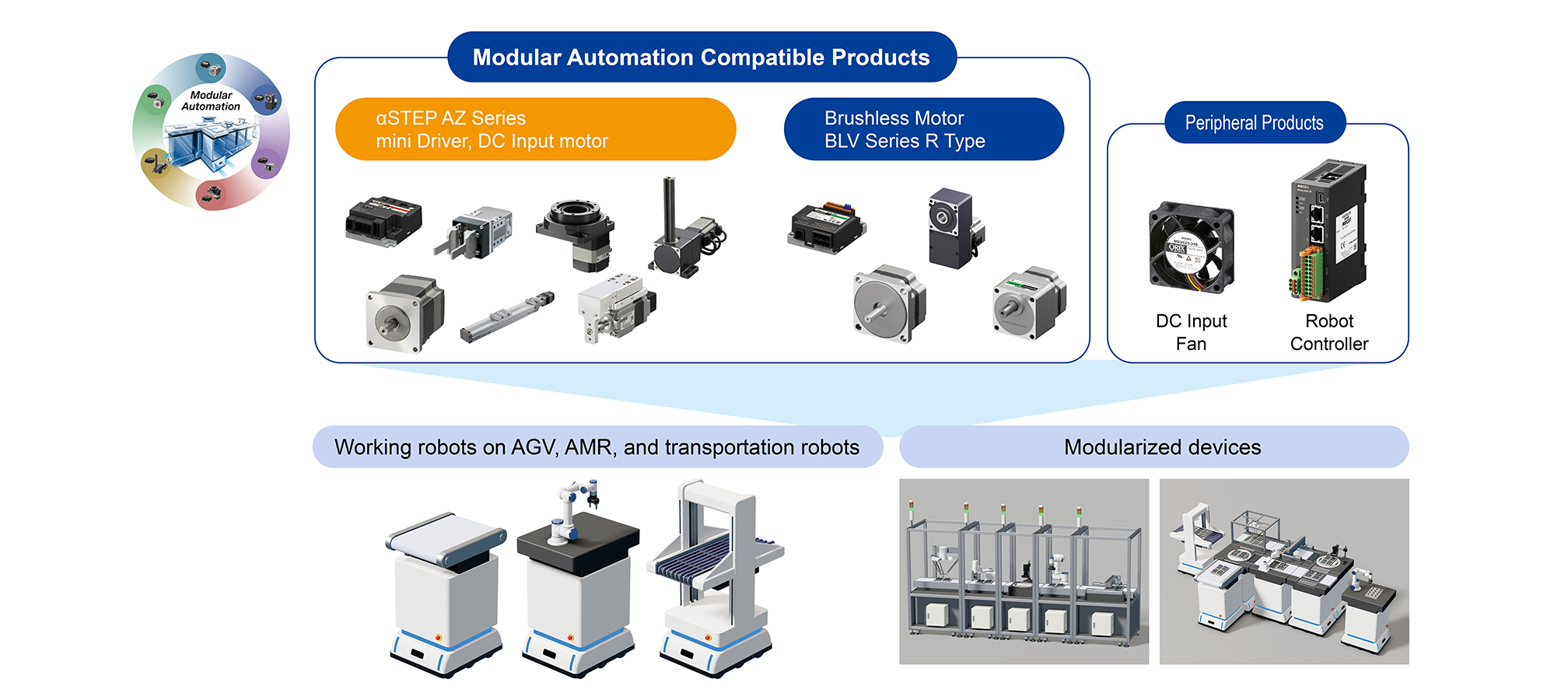

Two types of Modular automation products are available: “Brushless Motor BLV Series R Types,” which are designed for AGVs and AMRs and “AZ Series DC Input mini Drivers and Motor Actuators,” which are designed for automated machines mounted on AGVs and AMRs.

BLV Series R types are suitable for AGV and AMR wheel drives, and can operate at low speeds from 1 r/min, allowing them to achieve smooth driving. Both motors and drivers have become significantly smaller and lighter, making them useful for developing more compact battery-powered devices. Since they have a radial load of 1500 N (153 kgf) when the flange output head is assembled and a radial load of up to 2040 N (208 kgf) for hollow shaft flat gears, they are strong enough to meet the needs of larger workpieces and installation of robots and conveyors.

AZ Series DC input mini Drivers and Motor Actuators are designed for conveyors, hoisting devices, and robots mounted on AGVs and AMRs. We have a lineup of DC input motors, hollow rotary actuators, rack-and-pinion systems, electric linear slides, electric grippers, and compact electric cylinders. The αSTEP, which utilizes Oriental Motor’s proprietary closed-loop control, is equipped with an ABZO sensor. This enables it to realize a battery-free absolute system that eliminates the need for a home sensor and other sensors. The mini Driver is designed to be small and lightweight for embedded applications and to reduce control panel space, and also supports network control using EtherCAT and RS-485 to reduce distribution.

Examples of Transportation Robot Usage and Modularization Applications

We are currently receiving many inquiries about using “automation as a substitute for human workers.” A major electronic parts manufacturer has developed a technique in which AGV-mounted overhead robots grab electronic parts and then transport and transfer them between processes. This technique uses brushless motors for the wheels and αSTEP for the overhead robots.

Yamakoshi noted, “Brushless motors were used for the wheels because they required powerful, battery-powered, speed-controlled motor gears, as well as small drivers that could be installed in confined spaces. The key points in employing αSTEP for the working robots was that it met the needs of a battery-powered motor with high precision control. To accommodate space and weight constraints, the motor is compact and lightweight and the driver is small, achieves wire savings, and provides high installation flexibility.”

Many companies have been working on “modularization” for some time, and we have been receiving inquiries particularly on the issues of miniaturization and space savings.

Yamakoshi added, “In terms of modularization, it is important to select parts that are compact and lightweight, since equipment and electrical components must fit within limited dimensions to facilitate the miniaturization of equipment. It is also important to take into consideration the use of DC power and network control in order to enable the power supply and wiring to be separated for each module. Our compact, lightweight, network-controlled DC input products for Modular automation help customers solve their modularization challenges.”

Customers have a variety of initiatives and needs, and Oriental Motor will contribute to their efforts to realize layout-free automation through products and services that support Modular automation. Please feel free to contact us with any questions you may have. We will propose solutions that focus on using “automation as a substitute for human workers” and “modularization.”